Concentrated ink-supplying system with vibrating function

A technology of an ink supply device and a vibration device, which is applied in printing and other directions, and can solve problems such as increased cost of ink cartridges, adverse effects on picture quality, and lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will now be described in conjunction with the accompanying drawings.

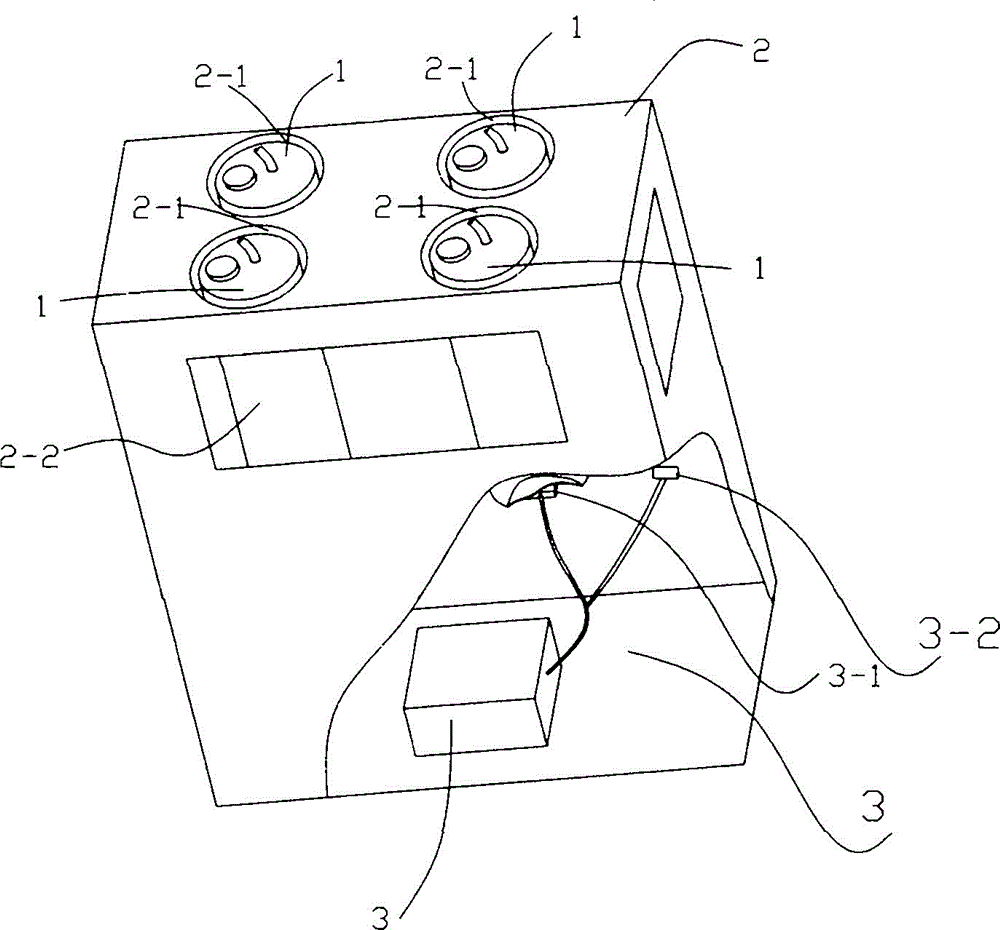

[0011] figure 1 It is a schematic diagram of the first preferred embodiment of the centralized ink supply device with vibration device in the present invention. Such as figure 1 As shown, the centralized ink supply device with vibration includes several ink bottles 1, a storage seat 2 and a vibrating device 3 for receiving the ink bottles, the storage seat is divided into upper and lower layers, and the storage The upper layer of the seat is provided with several storage tanks 2-1 for accommodating the ink bottles, and the lower layer is used to store the vibrating device 3, the vibrating device 3 includes a vibration generating element 3-1 and a control circuit board 3-2, and 1 bottle of several ink bottles The bottom is close to the upper surface of the upper and lower separation layer of the receiving seat 2, and the vibration generating element 3-1 is close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com