Striping device

A slitting device and slitting technology, applied in deburring devices, textiles and papermaking, fiber processing, etc., can solve problems such as poor slitting effect and inability to adjust the tension of slitting belts, so as to improve slitting quality, Improve the effect of slitting and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

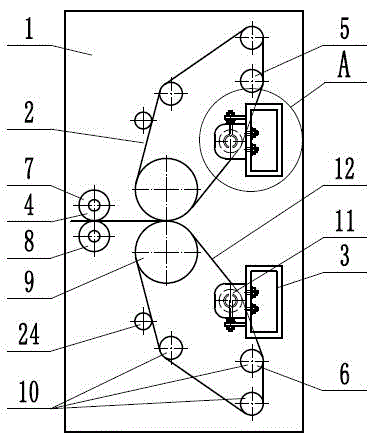

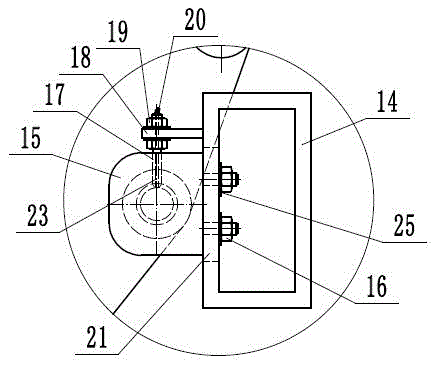

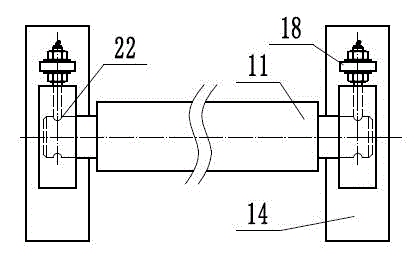

[0017] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a slitting device includes a frame 1, a slitting mechanism 2, and an adjusting mechanism 3. The slitting mechanism 2 realizes the rapid slitting of the fleece, which is beneficial to subsequent processing, and the adjusting mechanism 3 realizes the splitting. The adjustment of the tension of strip belt 12 is conducive to improving the stripping effect. The slitting mechanism 2 includes a net inlet component 4 , an upper slitting component 5 and a lower slitting component 6 . The web feeding assembly 4 includes an upper web feeding roller 7 and a lower web feeding roller 8, both of which are rotatably arranged on the frame 1, and are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com