Vaneless gas turbine power generation device

A gas turbine and power generation device technology, applied in the direction of gas turbine devices, machines/engines, mechanical equipment, etc., can solve the problems of difficult manufacturing, complex blade structure, high design requirements, etc., to solve manufacturing and maintenance, simplify system structure, and device structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

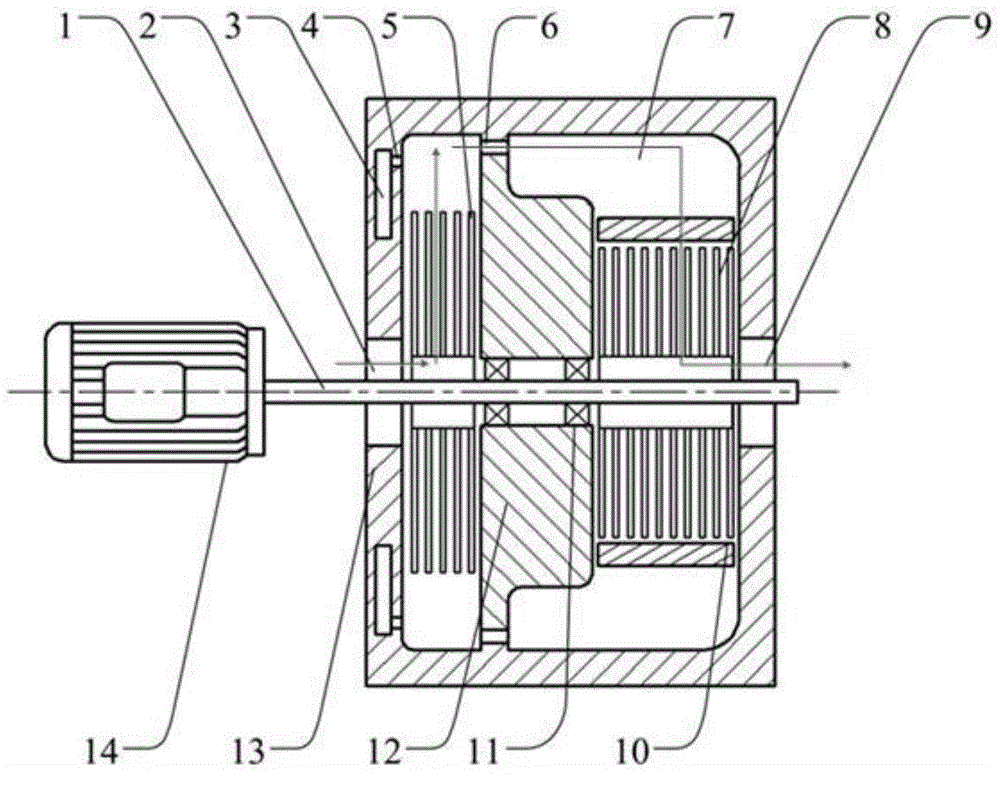

[0019] This embodiment provides a bladeless gas turbine power generation device, which includes: a gas turbine body and a motor 14 .

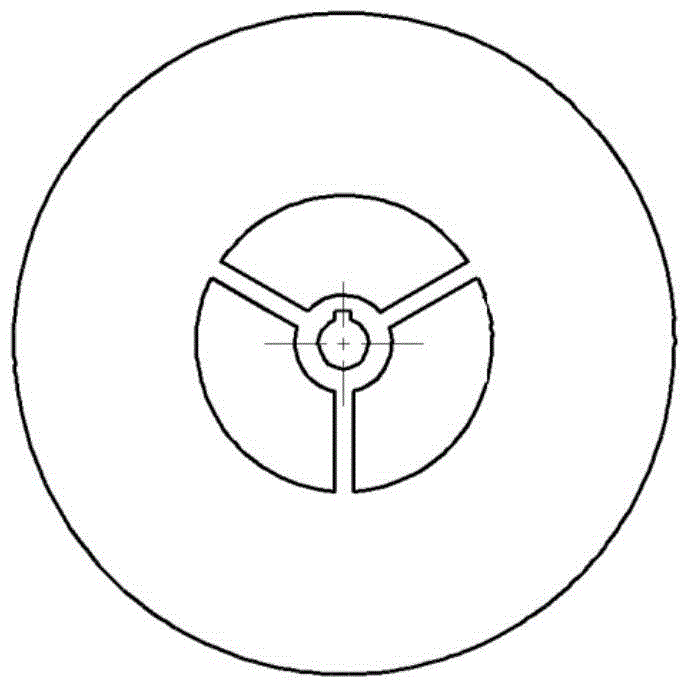

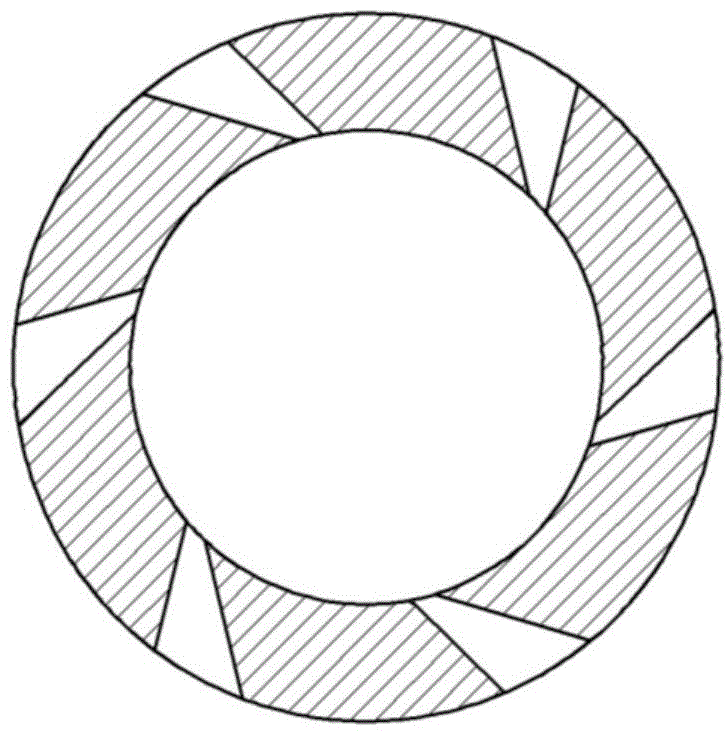

[0020] Wherein the gas turbine body comprises: housing 13, compressor disc group 5, turbine disc group 8 and gas guider 10; housing 13 two ends are respectively provided with air inlet 2 and air outlet 9, on the air inlet 2 side The housing 13 is provided with a fuel chamber 3 and a fuel nozzle 4; the interior of the housing 13 is divided into two cavities by a middle partition 12, wherein the cavity on the side of the air inlet 2 is a mixture chamber, and the side of the air outlet 9 The cavity is the combustion chamber 7; the combustion chamber 7 communicates with the gas mixture chamber through the flame holder 6 arranged on the intermediate partition 12; image 3 As shown, the gas guide 10 is arranged in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com