A machine vision-based online measurement system and method for spring dimensions

A measurement system and machine vision technology, applied in the direction of measurement devices, instruments, image data processing, etc., can solve the problems of waste economy, manual sampling inspection, loss, etc., to improve production efficiency, reduce scrap rate and rework rate, reliability and Effect of Stability Guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

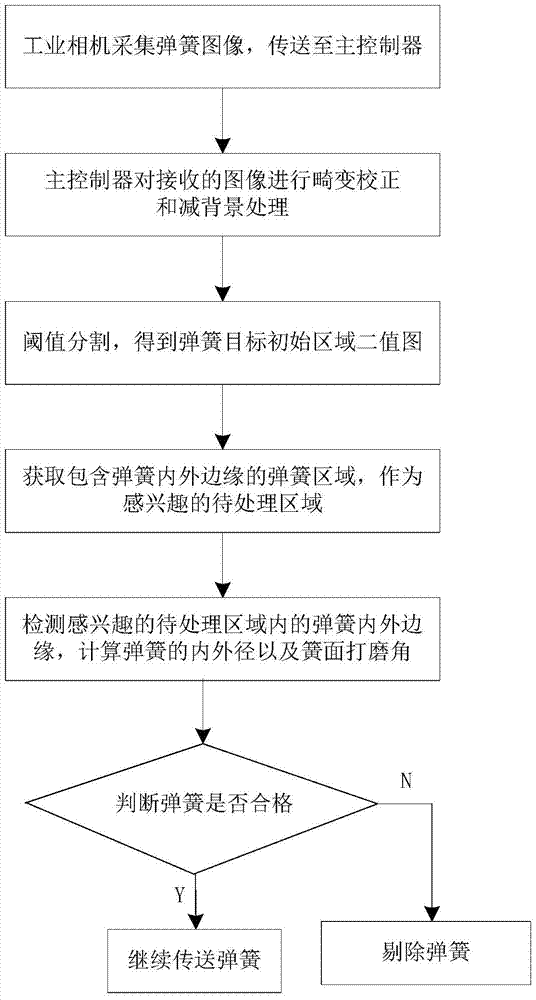

[0052] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

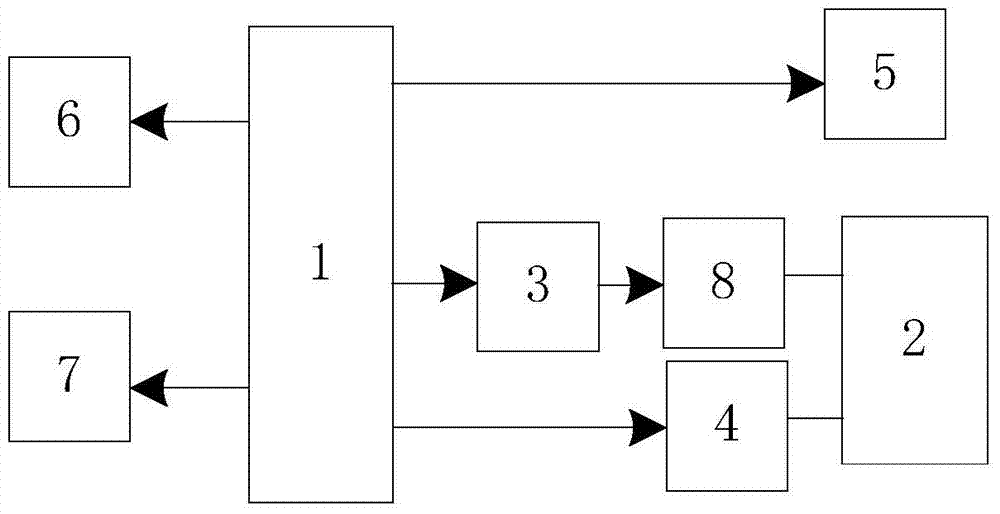

[0053] Such as figure 1 As shown, a machine vision-based spring size online measurement system includes:

[0054]The stage 2 is provided with a transmission mechanism 8 for transmitting the spring to be measured, and the transmission mechanism 8 is connected with the drive mechanism 3; the stage 2 is also provided with a reject mechanism 4, and the drive mechanism 3 and the reject mechanism 4 are Connect with main controller 1;

[0055] A light source, which is arranged above the spring to be tested, is used to provide illumination for the spring to be tested;

[0056] A light source controller, which is connected to the light source and used to control the on-off and intensity of the light source;

[0057] The industrial camera 5 is arranged directly above the spring to be tested, the industrial camera 5 is connected to the main controller 1, and the indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com