Encapsulated thin film and manufacturing method therefor, light emitting apparatus, display panel and display device

一种封装薄膜、基板的技术,应用在电固体器件、半导体器件、有机半导体器件等方向,能够解决成本高、难应用曲面显示屏、封装玻璃难弯曲性等问题,达到良好兼容、好可弯曲性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

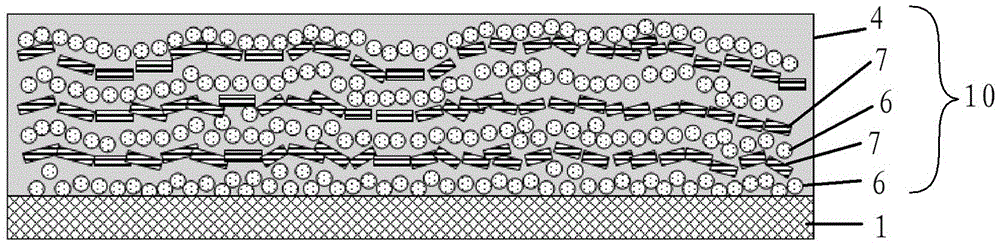

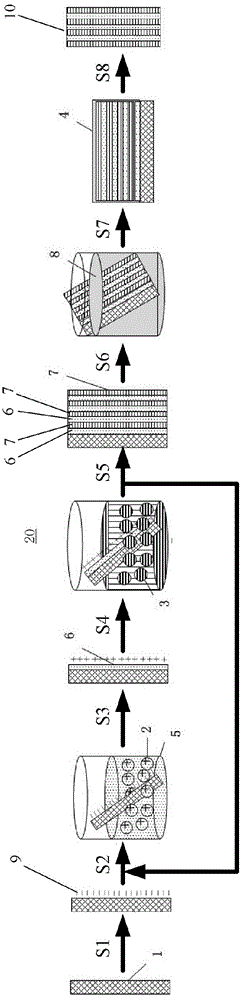

[0027] Below, reference will be made to the appended Figure 1-2 Various embodiments of the present invention are described in detail.

[0028] figure 2 is a flowchart 20 of making an encapsulation film according to one embodiment of the present invention. figure 2 The shown method of making the encapsulation film may comprise the following steps:

[0029] In step S1, the substrate 1 is pretreated so that its surface is positively charged or negatively charged. The substrate 1 is a conventional glass substrate or other deposition substrates. The pretreatment method used may be oxygen plasma treatment or other electrochemical treatment, the purpose of which is to make the surface of the substrate 1 be positively or negatively charged after the pretreatment. figure 2 As shown in step S1 of , the surface of the substrate 1 is negatively charged 9 after pretreatment. Alternatively, the surface of the substrate 1 may also be positively charged after pretreatment.

[0030] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com