A detection and correction method for fast and accurate acquisition of component center and deflection angle

A technology of deflection angle and components, which is applied in the field of image processing, can solve the problems of affecting the fitting accuracy, inaccurate fitting straight line, and large proportion of occupation, so as to reduce the influence of fitting accuracy, reduce the image range, and reduce the the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

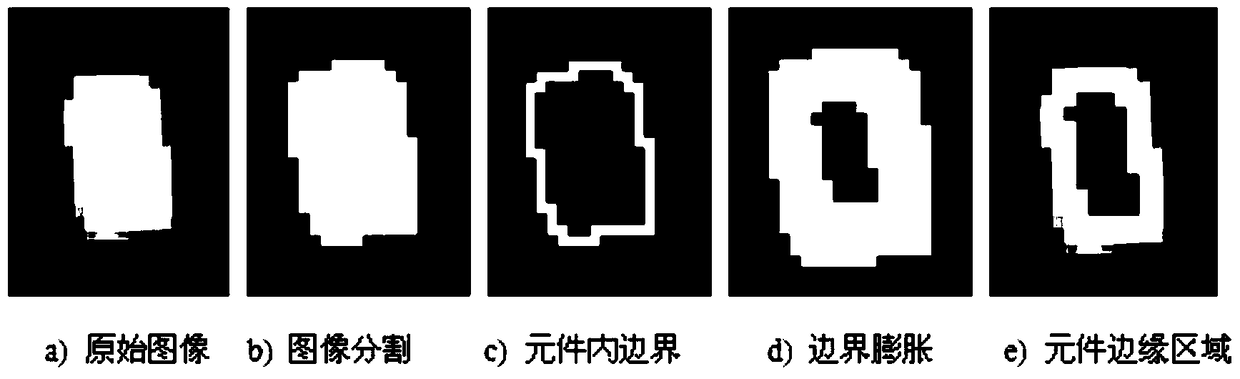

[0062] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0063] During the entire placement process of the placement machine, when the reference point is positioned and transformed into the machine coordinate system, the target placement position of the components on the PCB has been determined. Subsequently, the placement head drives the suction nozzle to move above the feeder to pick up the placement components and prepare for placement. Due to component transportation, feeding, mechanical positioning of the suction nozzle, and pneumatic suction, two problems may arise at this time: one is that the center of the suctioned component does not coincide with the center of the suction nozzle; the other is that the suction position of the component does not coincide with the target sticker. There is an angular deviation in the installation position, such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com