Fully-automatic positioning and sectioning type waste tobacco rod recycling machine

A waste cigarette, fully automatic technology, applied in tobacco, paper cigarette manufacturing, application, etc., can solve the problems of difficult tobacco sorting, poor control of depth, and different cutting positions, etc., to achieve a high degree of automation and high operating efficiency , The effect of accurate cutting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Now in conjunction with accompanying drawing, the present invention is described in detail.

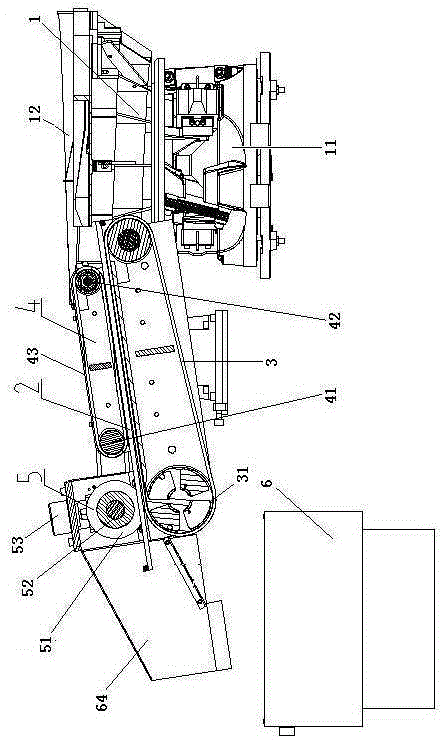

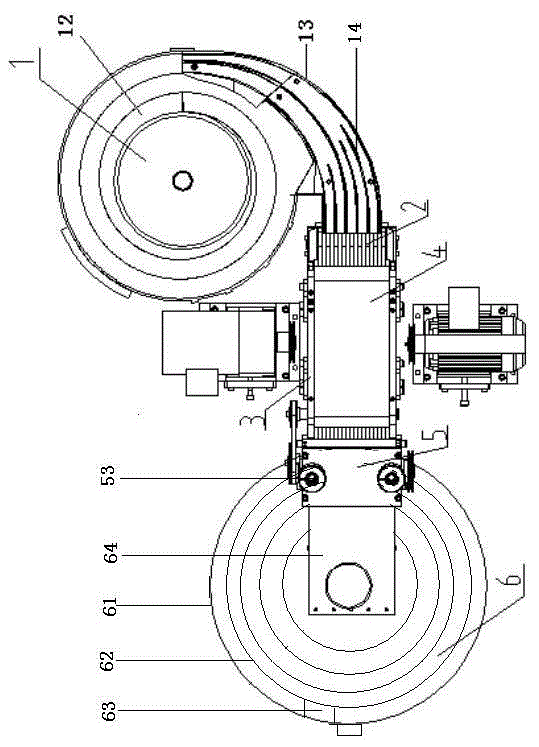

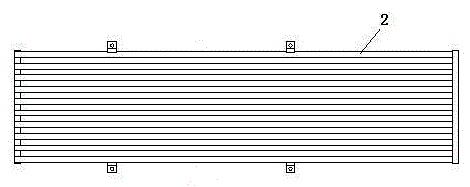

[0032] exist Figure 1-Figure 10 Among them, this automatic feeding, cutting and screening waste cigarette recycling machine includes automatic feeding device 1, cylindrical guide rail 2, conveyor belt 3, smoke rolling device 4, smoke cutting device 5 and vibrating screening device 6, automatic feeding The device 1 adopts a vibrating feeder 11. There is a vibrating machine at the bottom of the vibrating feeding machine 11. There is a vibrating plate 12 at the upper part of the vibrating feeding machine. The outer peripheral outlet of the vibrating plate 12 is provided with an arc-shaped guide groove 13; The cylindrical guide rails 2 installed on the frame parallel to each other and obliquely, the upper end of the cylindrical guide rail 2 is lower than the outlet of the arc guide groove 13 8 mm, there are several arc-shaped plates 14 in the arc-shaped guide groove 13, the numbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com