Ultrasonic auxiliary filtering membrane damage simulation test device and test method

An experimental device and ultrasonic technology, applied in the field of membrane separation, can solve problems such as affecting experimental results, large workload, and limited ultrasonic intensity range, and achieve the effects of comprehensive experimental data, reliable research results, and improved automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

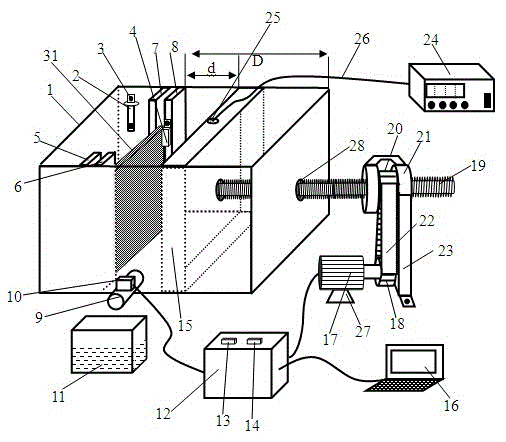

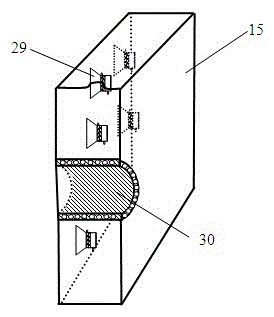

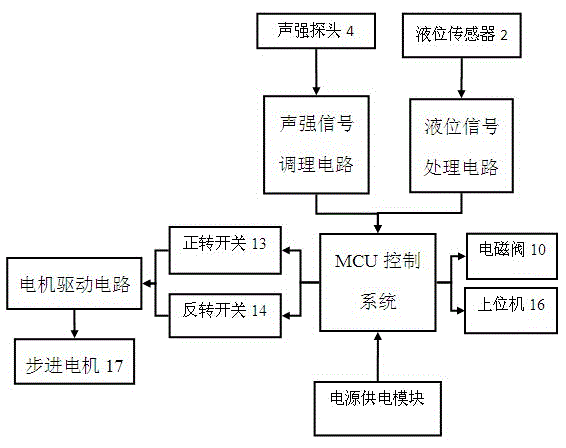

[0022] see figure 1 The overall structure of a kind of simulated ultrasonic filter-aided membrane loss experimental device of the present invention shown has an experimental pool 1, and the inside of the experimental pool 1 is a cavity, and a flat film 31 and an ultrasonic transducer box 15 are placed inside the experimental pool 1 . The ultrasonic transducer box 15 is vertically located on the right side inside the test pool 1, and divides the inside of the test pool 1 into left and right areas, and the left area stores the feed liquid. The front and back walls of the ultrasonic transducer box 15 are in sealed contact with the inner walls of the front and rear sides of the test pool 1 as much as possible to prevent the material liquid from the left area from infiltrating into the right area, and it is also necessary to ensure that the ultrasonic transducer box 15 can move left and right in the test pool 1. In the left area, a flat film 31 is vertically arranged, and the flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com