Double-vibration barrel-shaped stirring mill

A stirring mill and dual-vibration technology, applied in grain processing, etc., can solve the problems of high energy consumption, low efficiency, unsatisfactory dispersion effect, etc., and achieve the effects of narrow particle size distribution, increased crushing effect, improved production efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

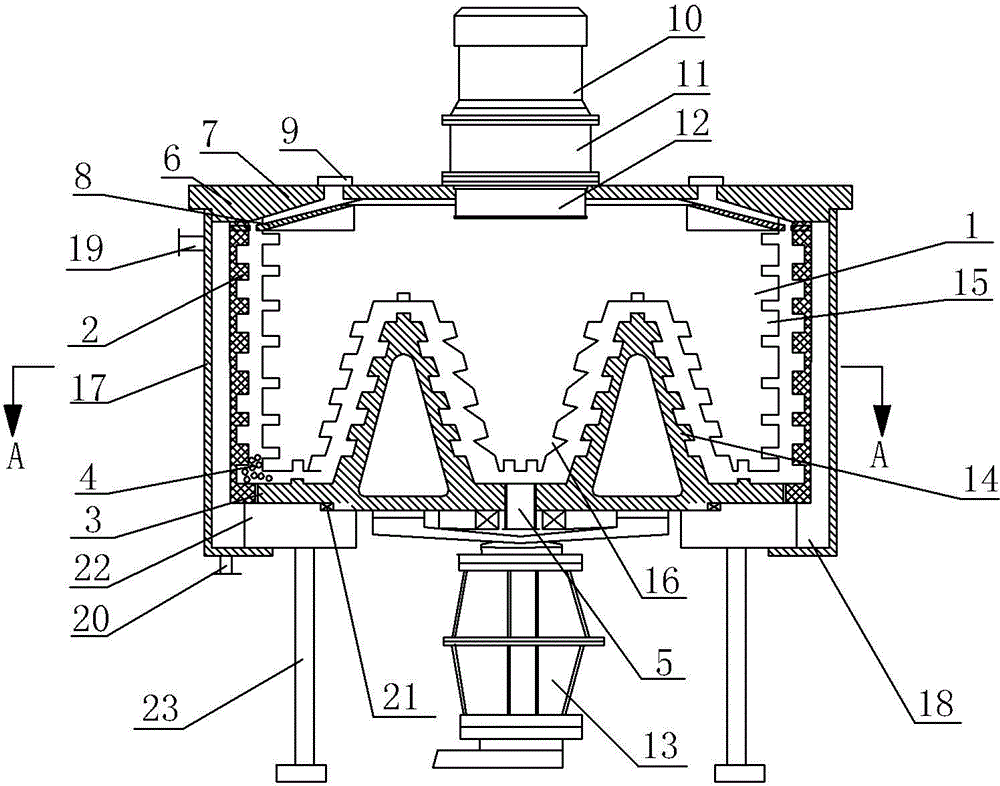

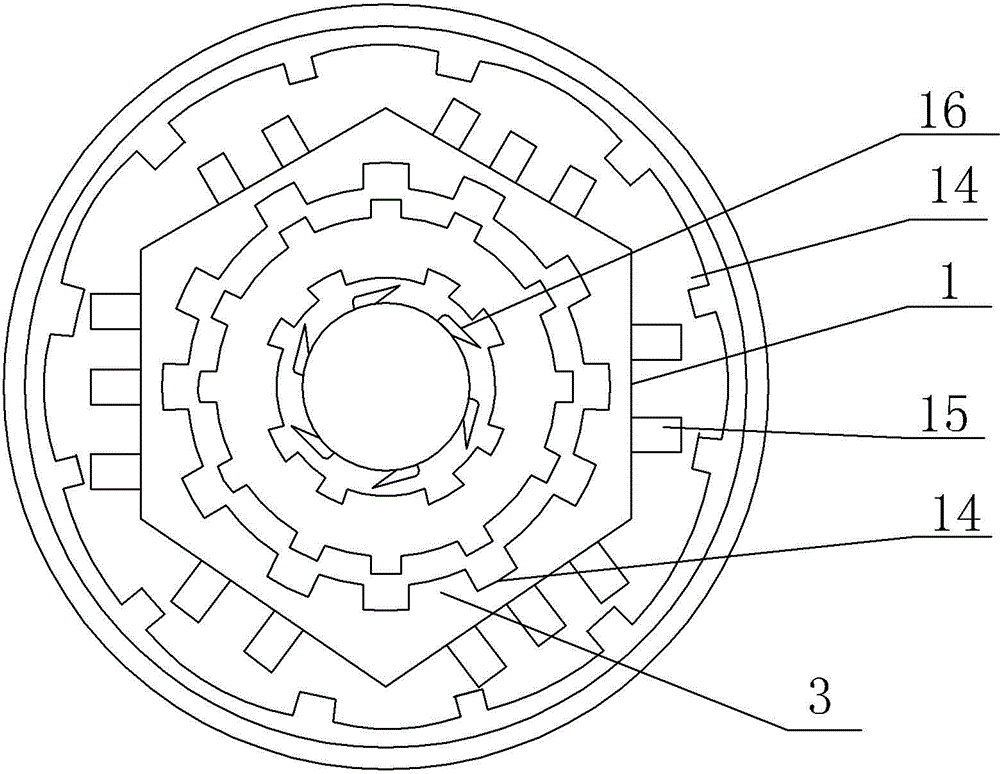

[0016] Such as figure 1 , figure 2 As shown, the present invention includes an upper inner grinding drum 1, the upper inner grinding drum 1 is a hexagonal cylinder, the upper inner grinding drum 1 is provided with a lower inner grinding drum 3 connected with the outer grinding drum 2, and the upper The inner grinding drum 1, the lower inner grinding drum 3, and the outer grinding drum 2 form a grinding channel, and the grinding channels formed between the upper inner grinding drum, the lower inner grinding drum, and the outer grinding drum are multiple and V-shaped. The grinding chamber effectively lengthens the grinding channel and shear force of the material, and can carry out shear grinding for a long time, with good shear grinding effect. There are grinding media 4 placed in the grinding channel, and the lower inner grinding drum 3 There is a feeding port 5 connected to the grinding channel at the center of the bottom end, and the upper inner grinding drum 1 and the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com