Integrated device and process for oil field operation high pressure cleaning and cam rotor type operation dirty oil and sewage recovery

A technology for sewage recycling and cleaning devices, which is applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc. High, reduce moving vehicles, the effect of high suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

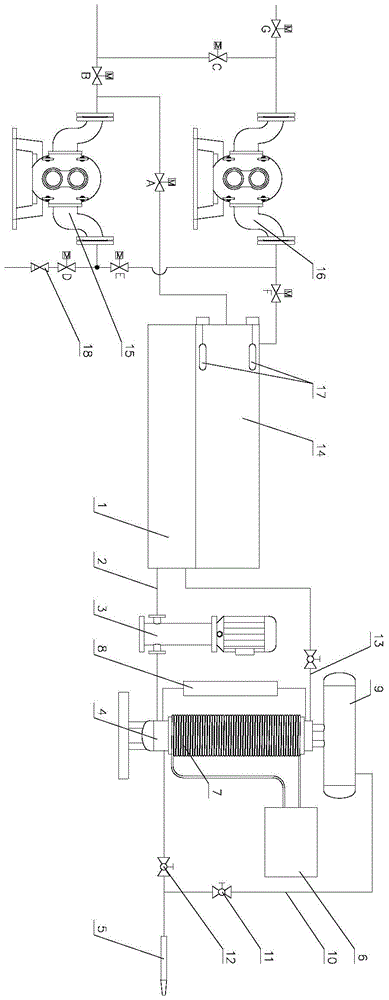

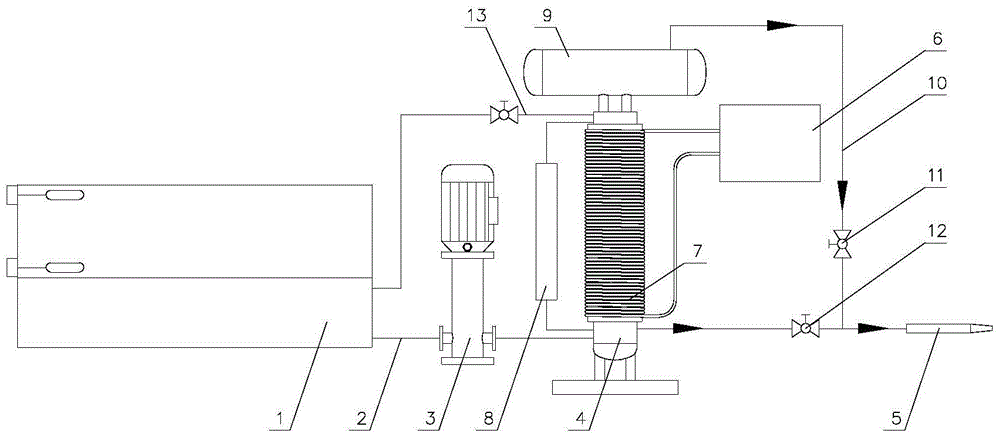

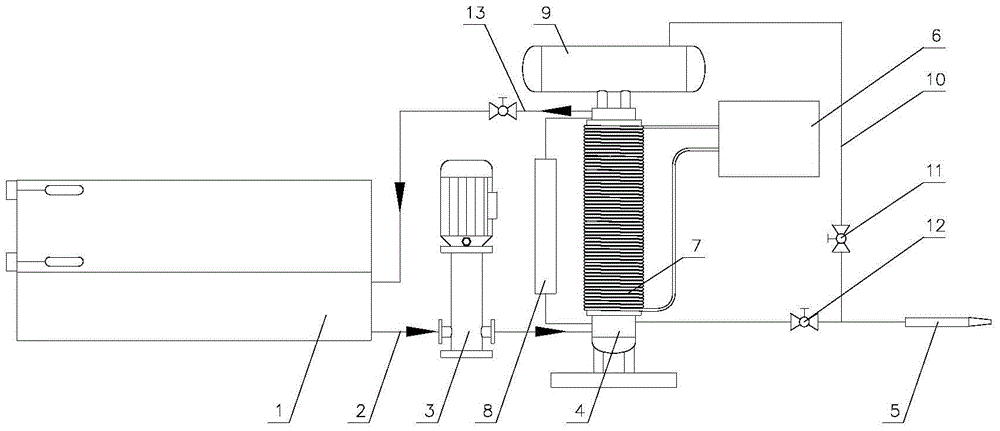

[0033] The present invention will be further described below in conjunction with accompanying drawing:

[0034] Depend on figure 1 , Figure 10 and Figure 14As shown, the integrated device for steam cleaning and waste oil and sewage recovery is composed of a steam cleaning device 25 and a waste oil and sewage recovery device 26, and also includes a power distribution cabinet 24. The steam cleaning device 25 includes a clean water storage tank 1 and a clean water storage tank 1. The outlet end is connected to the inlet port of the water replenishment pump 3 through the replenishment pipeline 2. The outlet end of the replenishment pump 3 is connected to the inlet port of the inner tank 4. Hot water is connected between the inlet end of the clean water storage tank 1 and the upper part of the inner tank 4. Circulation pipeline 13, hot water valve 12 is connected to the pipeline at the outlet end of inner tank 4, and hot water valve 12 is used to adjust the ratio of water vapor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com