Cardboard Insertion Device

A technology for inserting devices and cardboard, which is applied in packaging and other directions, can solve the problems of complex manufacturing and assembly process, insufficient connection, inconvenient maintenance and management, etc., and achieve the effect of simple and easy assembly process, compact and reasonable structure, and convenient maintenance and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

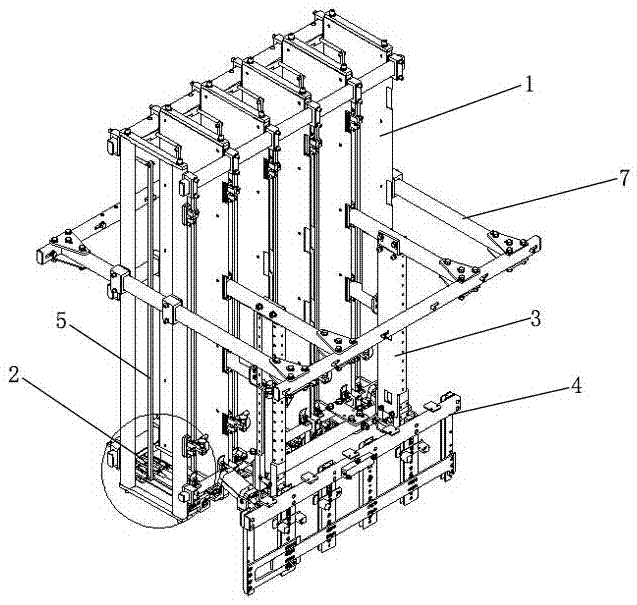

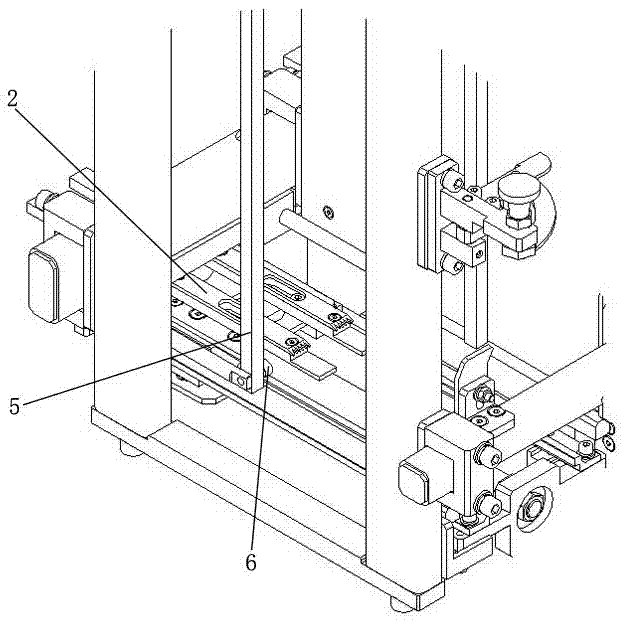

[0027] Such as figure 1 The shown cardboard inserting device of the present invention is applied in the automatic cardboard insertion process, and includes a cardboard warehouse 1 composed of several storage units, a cardboard pushing mechanism 2 , a lifting and turning mechanism 3 and a turning plate 4 . The cardboards are neatly stacked in advance in the cardboard warehouse 1, and the cardboards are transferred to the flap 4 one by one by the cardboard pushing mechanism 2, and then the flap 4 is driven by the lifting and turning mechanism 3 to lift and flip to complete the cardboard insertion operation.

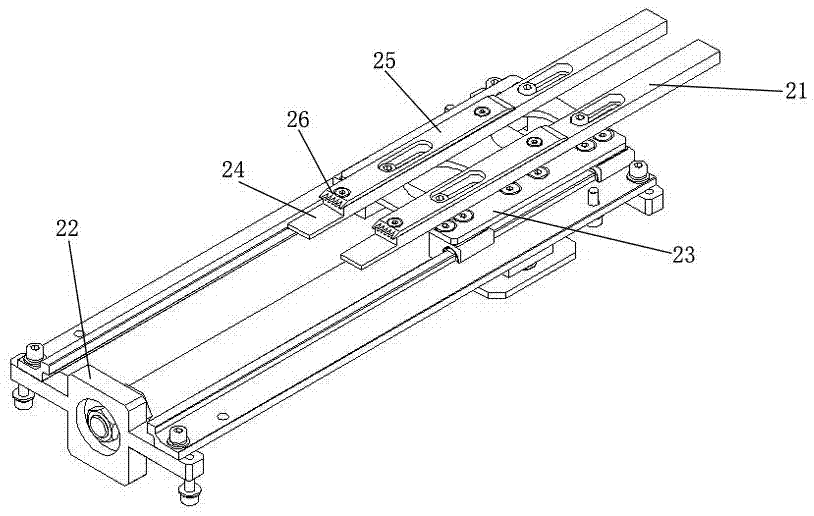

[0028] Such as image 3 As shown in , the cardboard pushing mechanism 2 includes a push plate 21 and a rodless cylinder 22 that drives the push plate 21 to perform linear reciprocating motion. The cardboard pushing mechanism 2 is located at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com