An Outdoor Enclosed Jet Fuse

A fuse and closed technology, which is applied in the field of outdoor closed spray fuses, can solve problems such as limited current carrying capacity, fuse breakdown, porcelain sleeve explosion, etc., to reduce overall weight, better sealing effect, and improve sealing performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

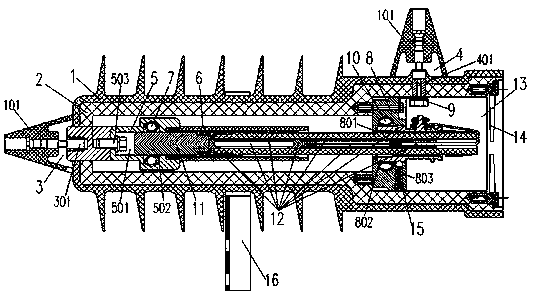

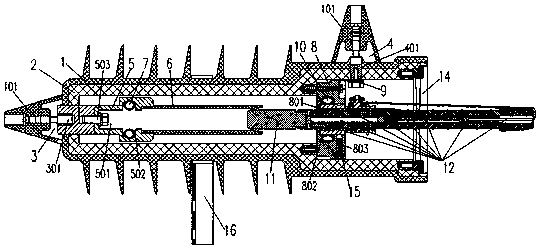

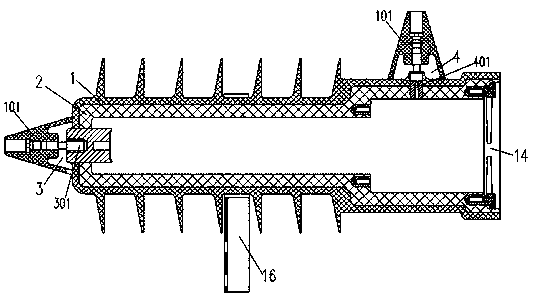

[0027] The present invention will be described in detail below in conjunction with specific embodiments. This embodiment provides detailed implementation methods and specific operation processes on the premise of the technical solution of the present invention.

[0028] As shown in the figure, the present invention is an outdoor enclosed spray fuse, which includes a fuse cover and a fuse injection mechanism arranged in the inner cavity of the fuse cover. The inner wall of the sleeve 1 is integrally connected with the resin bushing 2 formed by casting. One end of the silicone rubber sleeve 1 and the resin bushing 2 is the cable inlet 3, and the other end is the opening end 13 for loading or taking out the fuse injection mechanism. The side wall of the silicone rubber sleeve 1 and the resin liner 2 near the bottom is provided with a cable outlet 4 penetrating through the inner cavity, and the cable inlet 3 and the cable outlet 4 are respectively sealed and filled with an incoming...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com