Leaking stoppage assistant based on explosive-polymerization reaction and using method for leaking stoppage assistant

A polymerization reaction and explosive technology, which is applied in infrastructure engineering, construction, protection devices, etc., can solve problems such as inability to carry out on-site construction, and achieve the effects of improving plugging efficiency, reducing water pressure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

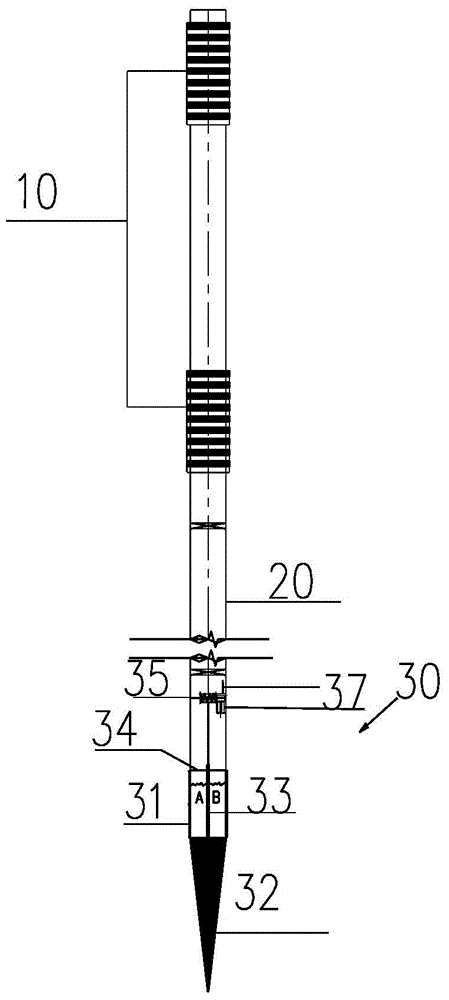

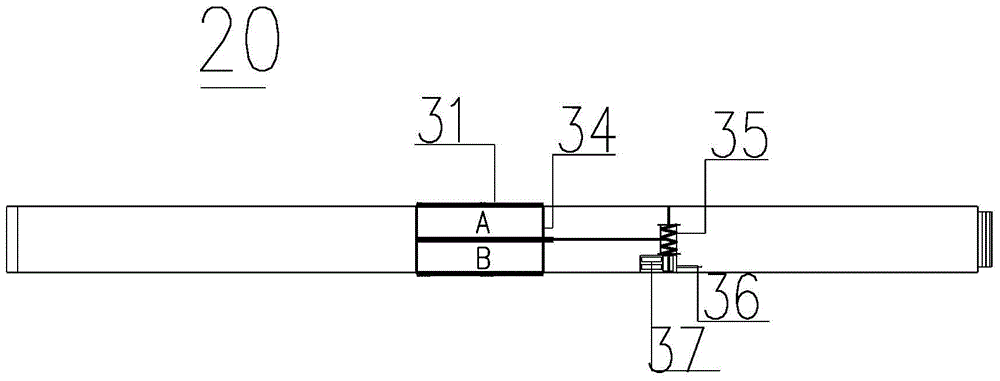

[0038] Combine below Figure 1 to Figure 7 The leak plugging assistant based on the explosive polymerization reaction and the method of use of the present invention are described in detail.

[0039] A plugging assistant based on explosive polymerization reaction, used for plugging exploration holes, a handle rod 10, at least one standard rod 20, one end rod 30, and an end rod 30 that are spirally connected from top to bottom. It includes an elastic filling bag 31 and a pointed cone 32. The elastic filling bag 31 is a closed structure. The outer side of the elastic filling bag 31 is evenly covered with friction thorns. The elastic filling bag 31 is separated into two juxtaposed by a blunt steel plate 33 arranged vertically. The storage room; the elastic filling capsule 31 is embedded between the lower end of the standard rod 20 and the upper end of the pointed cone 32, and the upper end of the pointed cone 32 passes through a solid shaft (not shown, set inside the blunt steel plat...

Embodiment 2

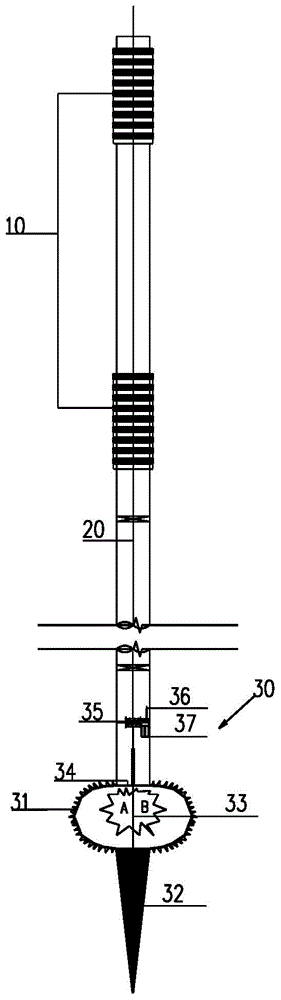

[0046] The difference from the first embodiment is that the standard rod 20 is provided with an elastic filling bag 31. Specifically, such as Image 6 As shown, in order to adapt to the plugging construction of exploration holes at different depths, the number of standard rods 20 can be increased or decreased accordingly; at the same time, in order to achieve a better plugging effect in the case of deeper exploration holes, you can While increasing the number of standard rods 20, increase the number of elastic filling bladders 31 from bottom to top, that is, elastic filling bladders 31 are provided in part of the standard rods 20 to achieve layer-by-layer sealing and gradually reduce water pressure Effect. Of course, each elastic filling bag 31 is connected with a wireless control device or a mechanical pull ring to facilitate the start of the explosive polymerization reaction inside the elastic filling bag 31, thereby improving the convenience of construction.

Embodiment 3

[0048] Correspondingly, this embodiment provides a method for using a plugging assistant based on an explosive polymerization reaction. Please refer to Figure 1 to Figure 7 , The use method of plugging assistant based on explosive polymerization reaction includes the following steps:

[0049] S001: The plugging assistant made by the factory is spare

[0050] S002: Insert the plugging assistant into a predetermined position in the exploration hole manually or mechanically;

[0051] S003: The blunt steel plate 33 is removed, the two storage chambers are connected, and the explosive polymerization reaction occurs when A and B contact, causing the elastic filling bag 31 to expand and generate friction with the hole wall of the exploration hole, thereby temporarily blocking the exploration hole ;

[0052] S004: Inject cement slurry to permanently plug the exploration hole.

[0053] Of course, according to the actual construction situation, after completing temporary plugging and performi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com