Non-welding stone curtain wall mounting structure and method

A technology for stone curtain wall and installation structure, applied in the direction of walls, building components, building structures, etc., can solve the problems of construction personnel and building property threats, and achieve the effect of eliminating fire hazards, facilitating maintenance, and improving flatness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

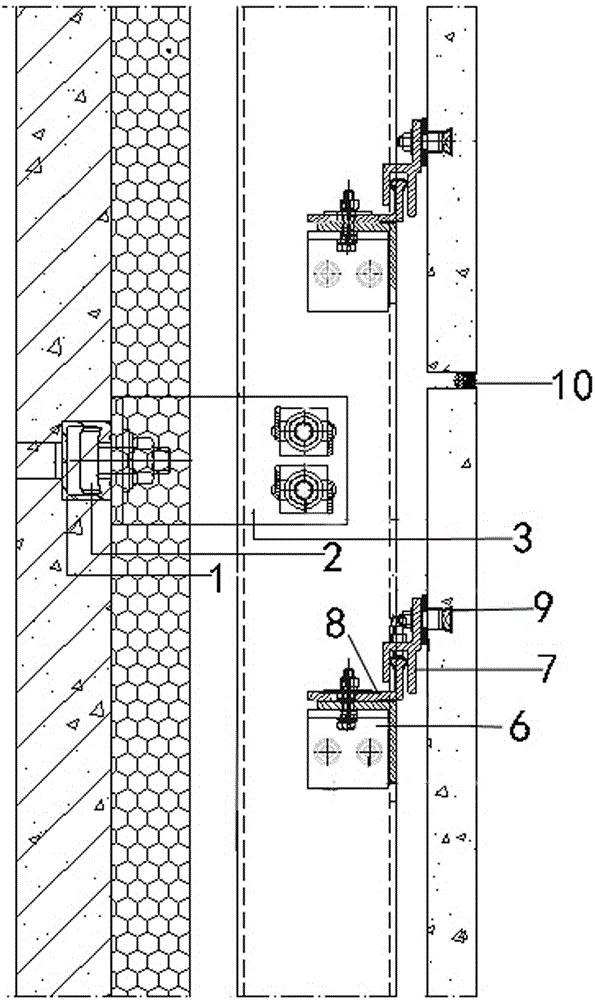

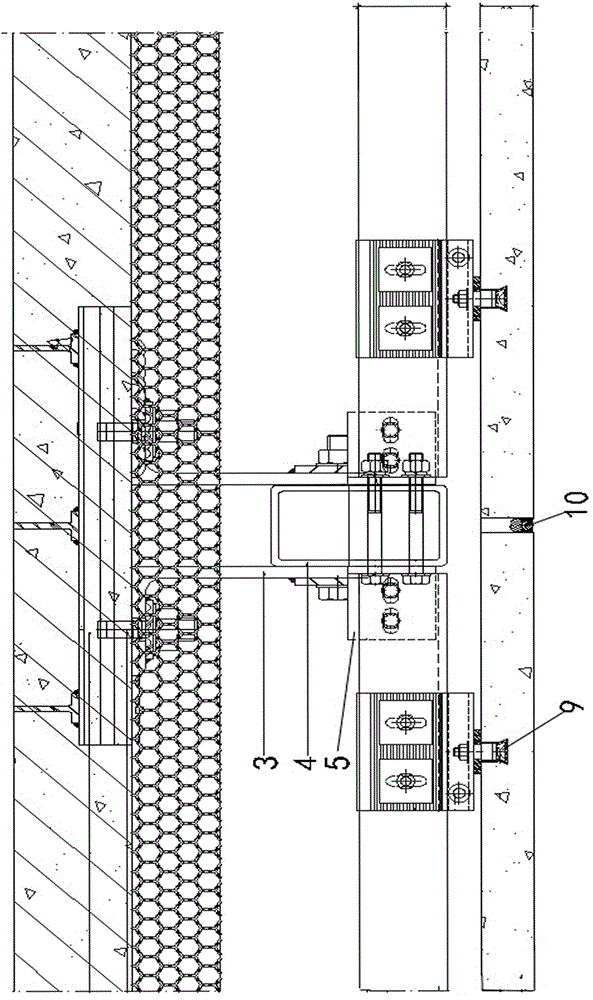

[0037] Example 1: Such as figure 1 , figure 2 As shown, a non-welded stone curtain wall installation structure includes at least one trough embedded piece 1, at least one T-bolt 2, at least one adapter piece, at least one first connecting piece 5, and at least one stone connecting component.

[0038] Among them, the trough embedded piece 1 is embedded in the reserved groove of the main body of the building.

[0039] The T-shaped head of the T-shaped bolt 2 is detachably placed in the trough-type embedded part 1, and the screw of the T-shaped bolt 2 extends out of the building body; the building body is provided with an insulation layer.

[0040] One end of the adapter 3 is connected to the T-bolt 2 through a nut, and the other end is connected to a specific column 4. Two adapters 3 are connected to each specific column 4, and the two adapters 3 are arranged oppositely. Wherein, each T-bolt 2 is connected to an adapter 3 correspondingly, two adjacent adapters 3 are arranged opposite...

Embodiment 2

[0052] Embodiment 2. The difference between this embodiment 2 and embodiment 1 is that: the hooking assembly includes the following components.

[0053] A first hook 7 is provided with a screw hole, and the first hook 7 is fixed to the stone back bolt 9 through the screw hole;

[0054] A second hook 8 is provided with a hook groove, the notch of the hook groove is vertically upward, and the first hook member 7 is hooked on the second hook member 8 through the hook groove ;

[0055] A second connecting piece 6 is used to connect the second hanging piece 8 with the curtain wall beam.

[0056] The first hook 7 has an "L" shape, and the second hook 8 has a reversed "h" shape. The first connecting piece 5 is an L-shaped connecting piece, and each connecting surface of the L-shaped connecting piece is provided with at least one oblong hole.

[0057] The screw holes mentioned in the above embodiments are round holes or oblong holes.

Embodiment 3

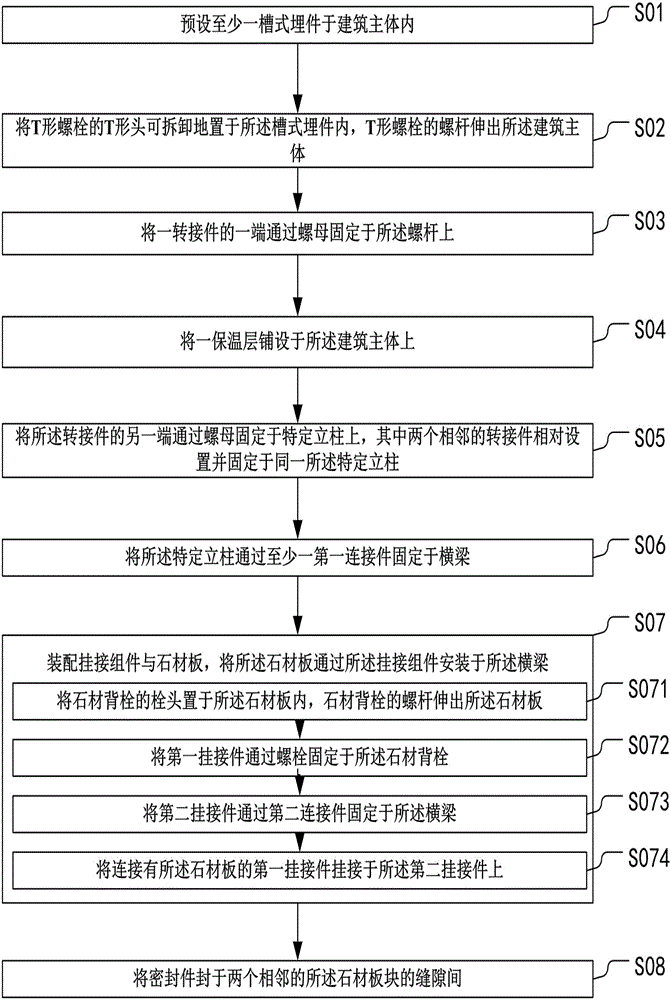

[0058] Example 3, such as image 3 As shown, a non-welded stone curtain wall installation method includes the following steps.

[0059] S01: preset at least one trough embedded part 1 in the main building.

[0060] S02: The T-shaped head of the T-shaped bolt 2 is detachably placed in the trough-type embedded part 1, and the screw of the T-shaped bolt 2 extends out of the main building.

[0061] S03: Fix one end of an adapter 3 to the screw through a nut.

[0062] S04: Lay an insulation layer on the main building.

[0063] S05: Fix the other end of the adapter 3 to the specific column 4 through a nut, wherein two adjacent adapters 3 are arranged oppositely and fixed to the same specific column 4.

[0064] S06: Fix the specific column 4 to the crossbeam through at least one first connecting piece 5.

[0065] S07: Assemble the hanging assembly and the stone slab, and install the stone slab on the beam through the hanging assembly

[0066] S08: Seal the sealing member 10 in the gap between tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com