Movable scaffold and construction process for pouring frame building through movable scaffold

A construction technology and scaffolding technology, applied in the direction of construction, building structure, housing structure support, etc., can solve the problems of heavy installation workload and non-reusable use of scaffolding, reduce time and installation workload, be easy to slide, and avoid moving bit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

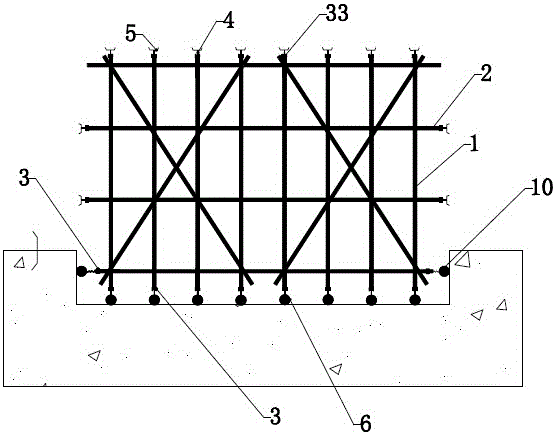

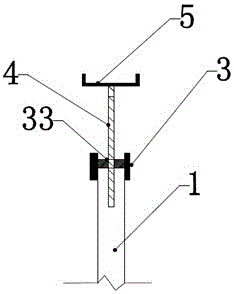

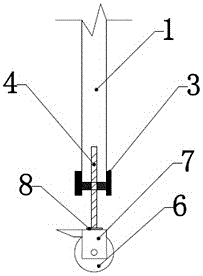

[0026] The mobile scaffold that present embodiment provides, as Figure 1~Figure 6 As shown, it includes several rows of vertically arranged standpipes 1 and horizontally arranged horizontal pipes 2, and each row of horizontal pipes 2 and standpipes 1 is provided with at least three rows, and the horizontal pipes 2 and standpipes 1 are connected. are all connected to each other to form a cube, and a pulley 6 is installed at the lower end of each vertical pipe 1; a telescopic connection device is installed at both ends of each horizontal pipe 2 and the upper end of the vertical pipe 1, and the telescopic A supporting plate 5 is installed above the connecting device; the telescopic connecting device includes an adjustable mounting support 3 cooperating with the horizontal pipe 1 or the vertical pipe 2, and a screw 4 matching the adjustable mounting support 3. The adjustable mounting support 3 includes a mounting cylinder 31, two semicircular pinch plates 32 symmetrically arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com