Composite Malay paint and construction process thereof

A construction technology and primer technology, applied in covering/lining, construction, building structure, etc., can solve the problems of poor stain resistance and poor hardness, achieve fast drying speed, improve hardness and adhesion, improve hardness and hardness. The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

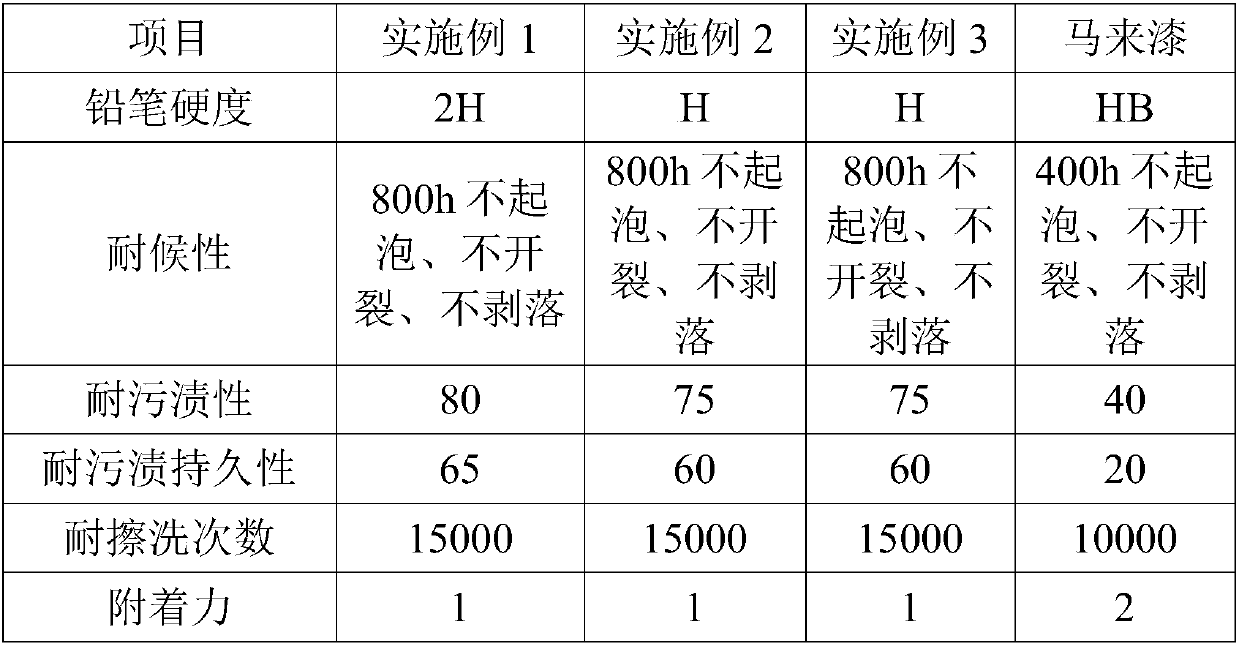

Examples

Embodiment 1

[0045] The UV primer, malay paint and fluorocarbon finish paint used in this implementation 1 are all from Hebei Chenyang Industry and Trade Group Co., Ltd.

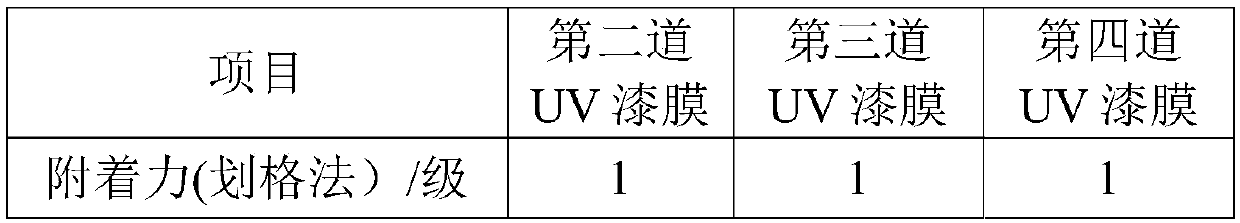

[0046] The embodiment of the present invention provides a kind of composite Malay paint, comprises UV primer, the Malay paint of coating on the described UV primer, the finishing paint of coating on the described UV primer; Wherein UV primer is 4 layers , and semi-cured and fully cured alternately by ultraviolet light irradiation. The finish paint is fluorocarbon finish paint.

[0047] The construction technology of above-mentioned composite Malay paint comprises the following steps:

[0048] Step a. Substrate treatment: sand with 320-grit sandpaper to remove stains and burrs on the laminated surface of the substrate.

[0049] Step b. Apply the first UV primer: heat the UV primer in a water bath to 40°C, and evenly coat the surface of the substrate with a coating amount of 20g / m 2 , and then irradiated with ultraviole...

Embodiment 2

[0058] The UV primer, malay paint and fluorocarbon finish paint used in this implementation 2 are all from Hebei Chenyang Industry and Trade Group Co., Ltd.

[0059] The embodiment of the present invention provides a kind of composite Malay paint, comprises UV primer, the Malay paint of coating on the described UV primer, the finishing paint of coating on the described UV primer; Wherein UV primer is 4 layers , and semi-cured and fully cured alternately by ultraviolet light irradiation. The finish paint is fluorocarbon finish paint.

[0060] The construction technology of above-mentioned composite Malay paint comprises the following steps:

[0061] Step a, Substrate treatment: Polish with 500-grit sandpaper to remove stains and burrs on the surface of the substrate.

[0062] Step b. Apply the first UV primer: heat the UV primer in a water bath to 60°C, and evenly coat the surface of the substrate with a coating amount of 25g / m 2 , and then irradiated with ultraviolet light ...

Embodiment 3

[0071] The UV primer, Malay paint and fluorocarbon finish paint used in this implementation 3 are all from Hebei Chenyang Industry and Trade Group Co., Ltd., and the slow drying agent is BASF FE302X.

[0072] The embodiment of the present invention provides a kind of composite Malay paint, comprises UV primer, the Malay paint of coating on the described UV primer, the finishing paint of coating on the described UV primer; Wherein UV primer is 4 layers , and semi-cured and fully cured alternately by ultraviolet light irradiation. The finish paint is fluorocarbon finish paint.

[0073] Above-mentioned composite Malay paint construction technique, comprises the following steps:

[0074] Step a, Substrate treatment: Polish with 400-grit sandpaper to remove stains and burrs on the surface of the substrate.

[0075] Step b. Apply the first UV primer: heat the UV primer in a water bath to 50°C, and evenly coat the surface of the substrate with a coating amount of 15g / m 2 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com