Duct piece hanging and conveying device applicable to miniature tunneling machine

A technology of tunnel boring machine and hoisting device, which is applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as inconvenience of manual operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

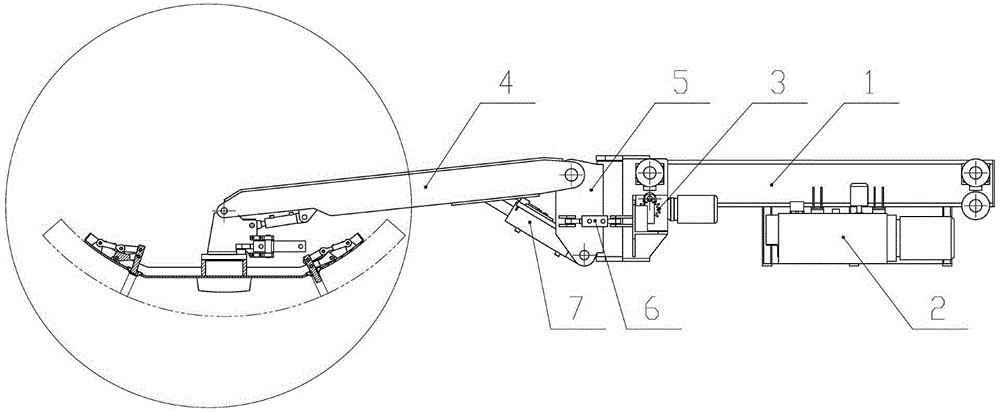

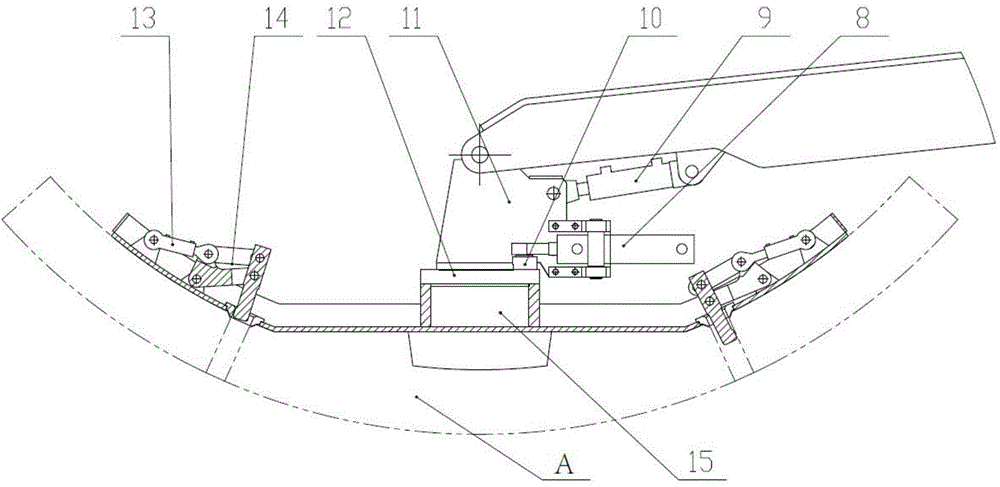

[0012] Referring to the accompanying drawings, a segment hoisting device adapted to a miniature tunnel boring machine mainly includes a traveling mechanism 1, a hydraulic unit 2, a traveling drive unit 3, a lifting arm 4, a lifting arm seat 5, a lifting arm rotating cylinder 6, a lifting arm Arm lift cylinder 7, segment rotation cylinder 8, compensation cylinder 9, rotation cylinder drive shaft 10, rotation support seat 11, rotation support 12, segment clamping cylinder 13, segment clamping mechanism 14, segment grabbing seat 15 , the traveling mechanism 1 is installed on the track beam, and the forward and backward movement of the crane is realized through the traveling drive unit 3, which is fixed on the traveling mechanism 1; the hydraulic unit 2 is suspended on the traveling mechanism 1, and can be forward and backward together with the crane Movement; the lifting arm seat 5 is pinned to the walking mechanism 1, and can move left and right; the lifting arm 4 is pinned to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com