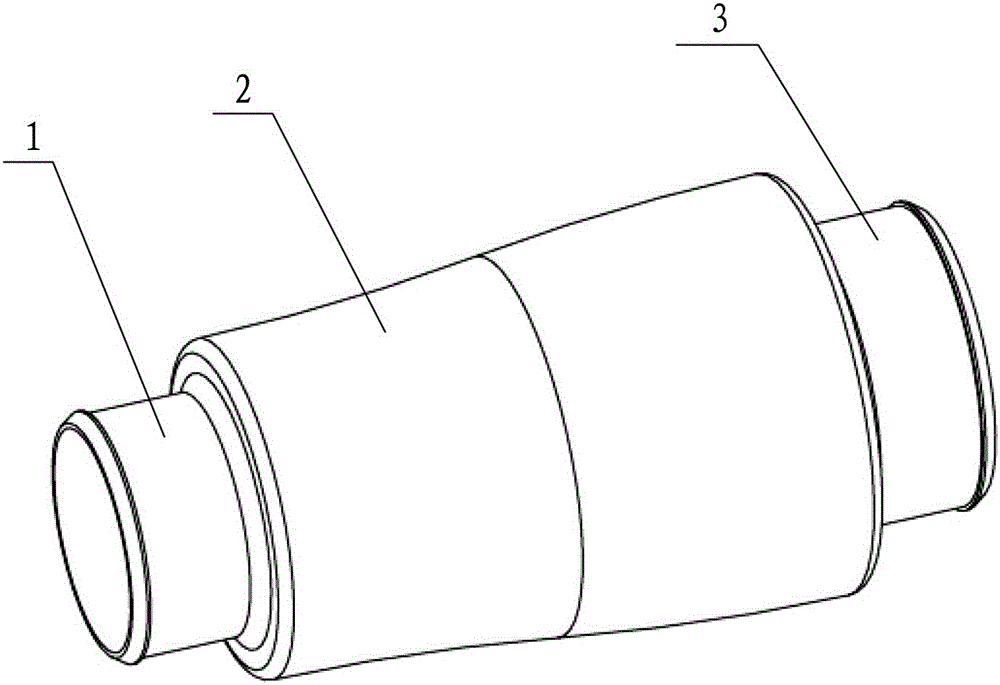

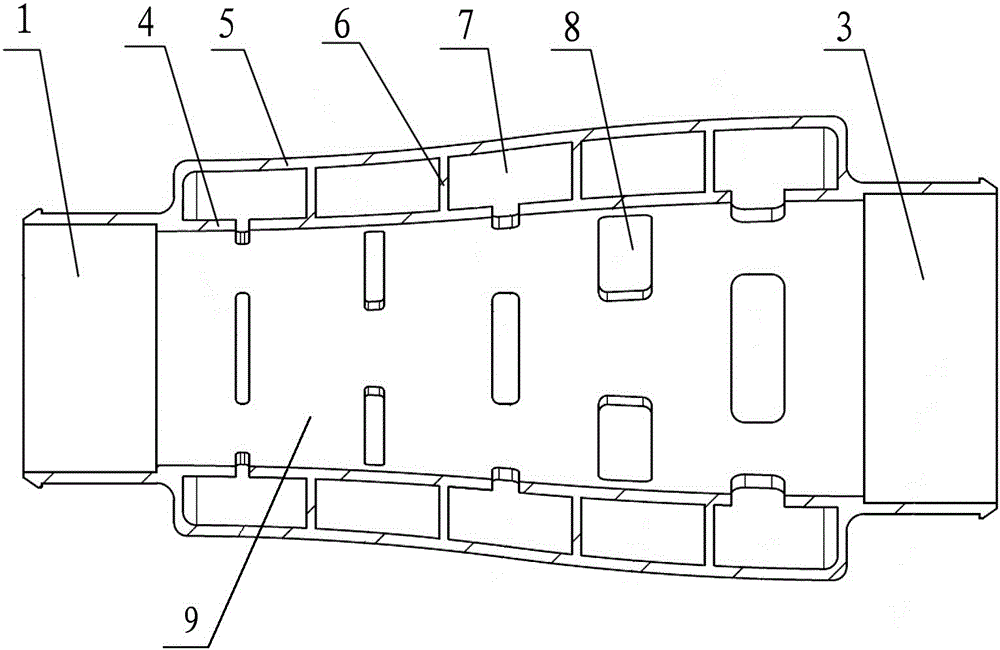

Multicavity resonance muffler

A muffler and resonance cavity technology, which is applied in mufflers, machines/engines, engine components, etc., to improve NVH, avoid resonance mutual interference, and improve the noise reduction effect of the overall structure of the noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the present invention easy to understand, according to figure 1 with figure 2 Describe concrete structure of the present invention in detail, embodiment: as figure 1 with 2 As shown, a multi-cavity resonance muffler includes a cylinder body 2 with an airflow outlet 1, an airflow inlet 3 and a ventilation cavity 9. The cylinder body is a conical cylinder with an airflow outlet diameter smaller than the airflow inlet diameter, and a circle is formed in the cylinder body. The platform-shaped ventilation cavity 9 has a trapezoidal overall axial section, and the cylinder wall has a double-layer structure with an inner cylinder wall 4 and an outer cylinder wall 5, and a cavity interlayer is spaced between the inner cylinder wall and the outer cylinder wall , the angle between the inner cylinder wall 4 and the axis of the cylinder wall double-layer structure is smaller than the angle between the outer cylinder wall 5 and the axis, and a plurality of annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com