Retractable type exhaust pipe penetration piece

A technology for exhaust pipes and cabin passages, which is applied in the field of retractable exhaust pipe cabin passages, can solve the problems that the cabin passages cannot be well protected from rain, cannot be easily changed, and have poor performance, so as to prevent rainwater from entering the cabin. Effects on the inside of the wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

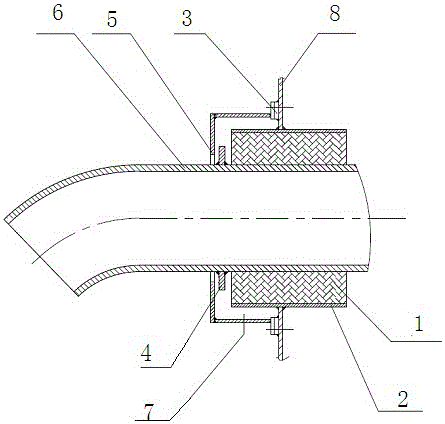

[0009] like figure 1 As shown in the figure, a retractable exhaust pipe cabin is composed of a heat insulating material 1 and a sleeve 2. The sleeve 2 is placed on both sides of the exhaust pipe 6 through the heat insulating material 1. On the sleeve 2 A bulkhead 8 is provided, the bulkhead 8 is vertically provided with an installation seat plate 3, and the installation seat plate 3 is horizontally provided with a rainproof cover 5, and the other end of the rainproof cover 5 is placed on the exhaust pipe 6, and the rainproof cover A water retaining ring 4 is provided between 5 and the casing 2 .

[0010] The rainproof cover 5 is provided with a drain hole 7 .

[0011] The principle is as follows:

[0012] The casing 2 is welded on the opening of the bulkhead 8, and the water retaining ring 4 is spot welded on the exhaust pipe 6 when the pipe is prefabricated. After the exhaust pipe 6 is positioned, it is adjusted to a suitable position and then the water retaining ring 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com