Combustor with adjustable flame

A burner and flame technology, used in burners, liquid fuel burners, combustion methods, etc., can solve the problems of thermal shock of the filter body, narrow adjustment range, unfavorable fuel economy, etc., and achieve the effect of saving energy and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

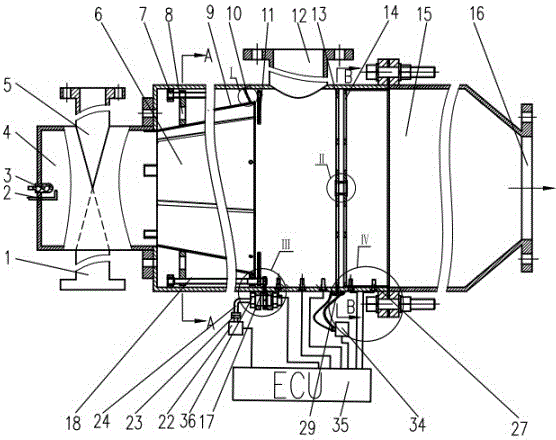

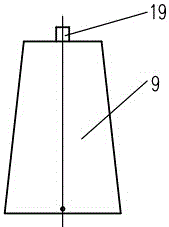

[0030] According to attached figure 1 It can be seen that the present invention specifically relates to a burner with adjustable flame, which is mainly used for fuel injection combustion-supporting regeneration process of diesel particulate filter, and specifically includes oil-gas mixing chamber 4, combustion chamber 6 and filter body section 15, three The latter are sequentially connected by flanges to form a whole, constituting the main body of the burner. Air inlets and fuel injection ignition devices are distributed on the surface of the oil-gas mixing chamber 4, and a total exhaust port 16 is provided at the filter body section 15, and a filter body is arranged inside the filter body section 15, and the filter body can remove carbon in the exhaust gas of a diesel engine. Particles are intercepted to achieve the purpose of purifying the exhaust gas of the diesel engine. An engine exhaust gas inlet 12 is provided on the side of the combustion chamber 6 . The difference be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com