Penetrating reverse-flow type fluidization drying tower

A drying tower and fluidization technology, applied in the direction of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of heat consumption, low efficiency, high energy consumption, etc., and achieve low power consumption of fans, control Subtle, dry quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

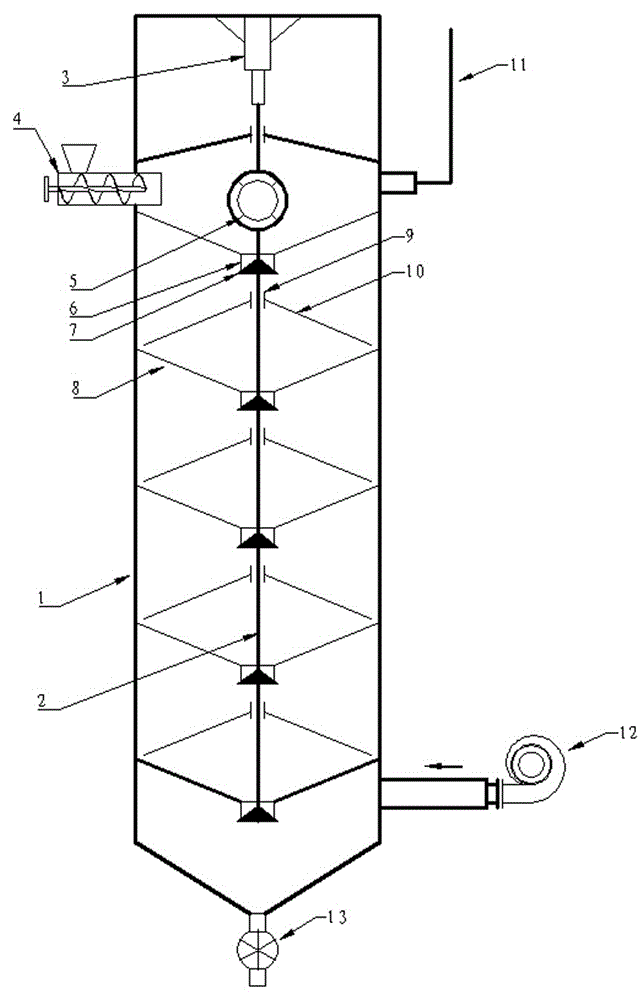

[0018] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0019] Such as figure 1 As shown in the penetrating countercurrent fluidized drying tower, the top of the drying tower 1 is equipped with a hydraulic expansion device 3 connected to the transmission shaft 2, the transmission shaft 2 runs through the tower body and can be driven up and down by the hydraulic expansion device 3, and the transmission shaft 2 is equipped with a vibration The source 5 transmits vibration; the drying tower body 1 is provided with a plurality of layered repeating structures composed of a sieve hole cone cover 10 and a sieve hole cone plate 8, and there is a certain gap between the cone plate 8 and the cone cover 10 and they are all connected by elastic It is fixed on the tower wall; the conical disk 8 and the conical cover 10 are respectively connected to the discharge pipe 6 and the shaft sleeve 9, and there are multiple conical plugs 7 on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com