Shock wave pressure test installation structure for shock tube calibration

A technology of pressure testing and installation structure, applied in the direction of force/torque/work measuring instrument calibration/testing, measuring devices, instruments, etc., can solve the problem that the shock wave ground reflection pressure test system cannot be dynamically calibrated, and the shock wave ground reflection pressure cannot be obtained. Test system dynamic characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

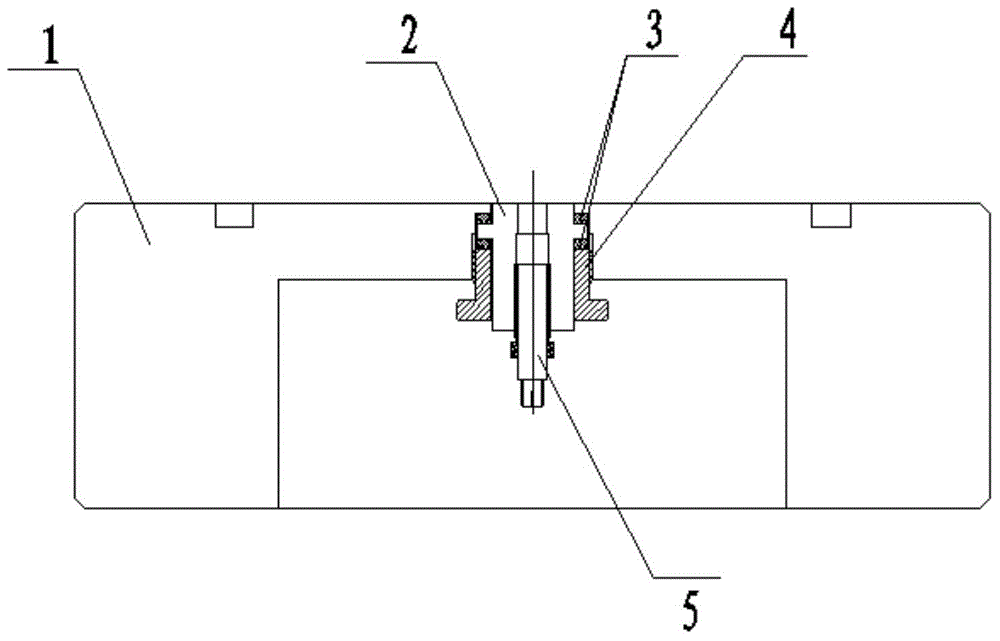

[0025] Use the PCB 113 type pressure sensor as the sensor to be calibrated, install it in the assembly, put two buffer gaskets on the assembly, and fix the assembly on the mounting base through the clamping piece.

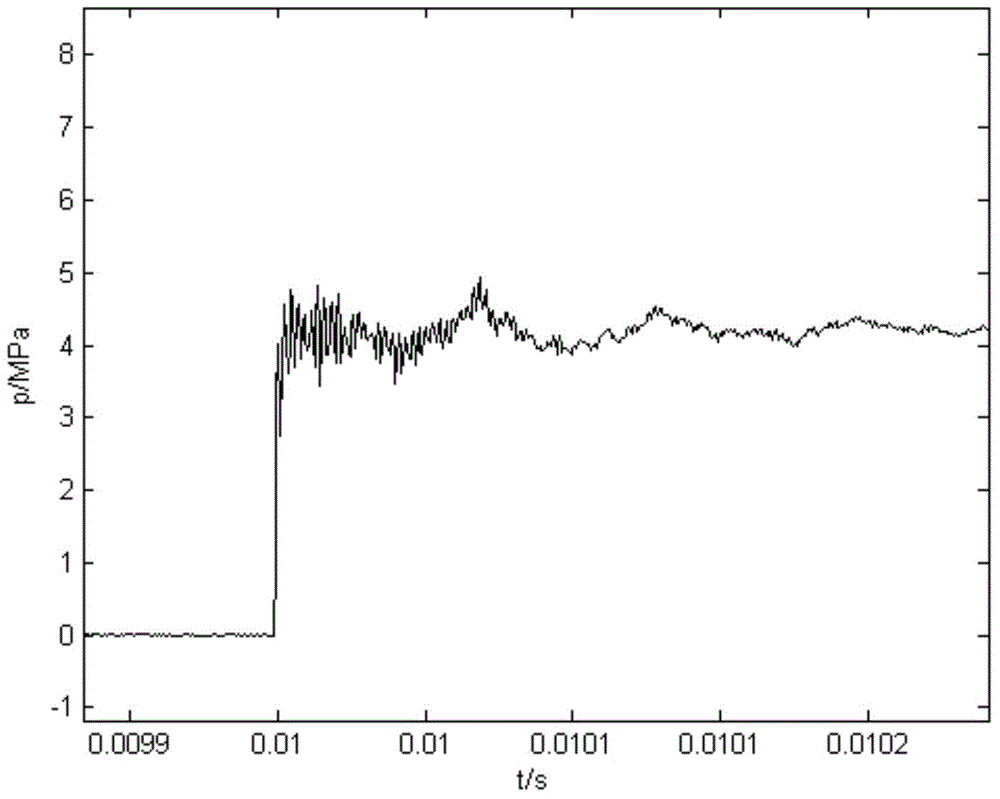

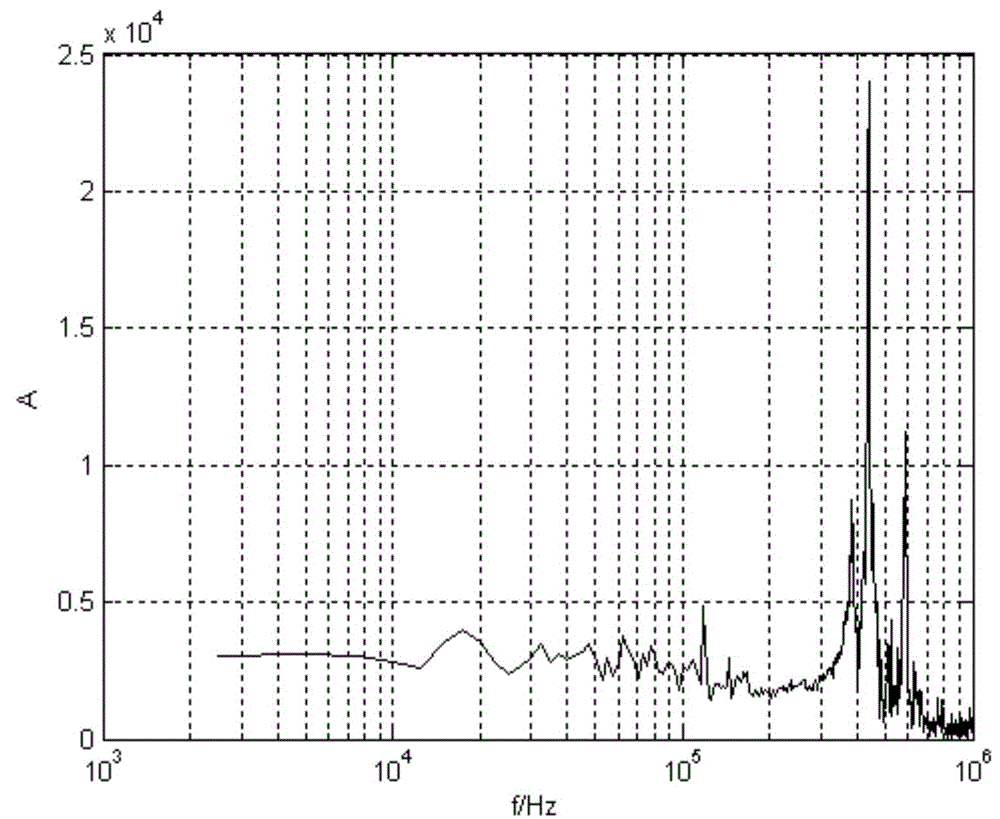

[0026] Put the sealing ring in the empty groove of the mounting seat, place it at the end of the GXJ-100s high-pressure shock tube developed by 204, and start the hydraulic cylinder to seal the low-pressure section of the shock tube. After installing the diaphragm in the sandwiched section of the shock tube, seal the sandwiched section and the high-pressure section. First inflate the low-pressure section, then inflate the sandwich section, then inflate the high-pressure section, and finally deflate the sandwich section, the diaphragm ruptures, and an ideal step wave acts on the mounting seat. The pressure signal output by the pressure sensor is as figure 2 As shown, it can be seen that in addition to the resonance signal (500kHz) of the pressure sensor and the os...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com