An online abnormality early warning and control device for non-woven fabric fibers

A technology of control devices and non-woven fabrics, applied in measuring devices, material analysis through optical means, instruments, etc., can solve the problems of low controllable rate of abnormal swallowing and limited warning distance, so as to avoid a large number of defective products and prolong The effect of early warning distance and high controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0025] It should be understood that the "first" and "second" mentioned in the following embodiments do not represent any absolute distinction relationship in structure or function, but are only for the sake of clarity and simplicity of description. In this embodiment, the "top" and "bottom" mentioned are defined in the usual sense, for example, referring to the definition of the direction of gravity, the direction of gravity is downward, the opposite direction is upward, and similarly the upper is the top Or top, and below is bottom or bottom.

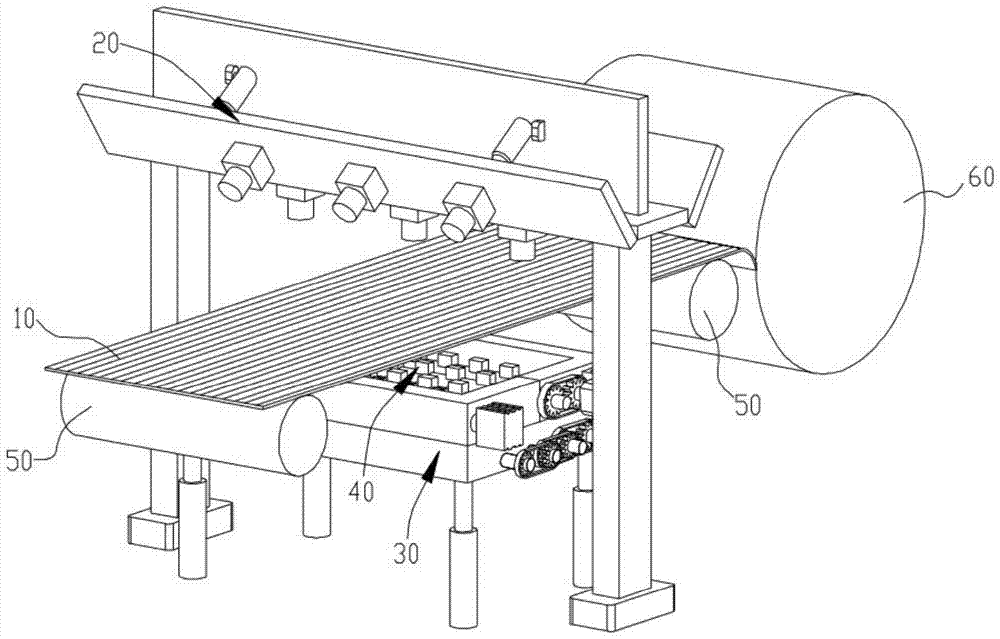

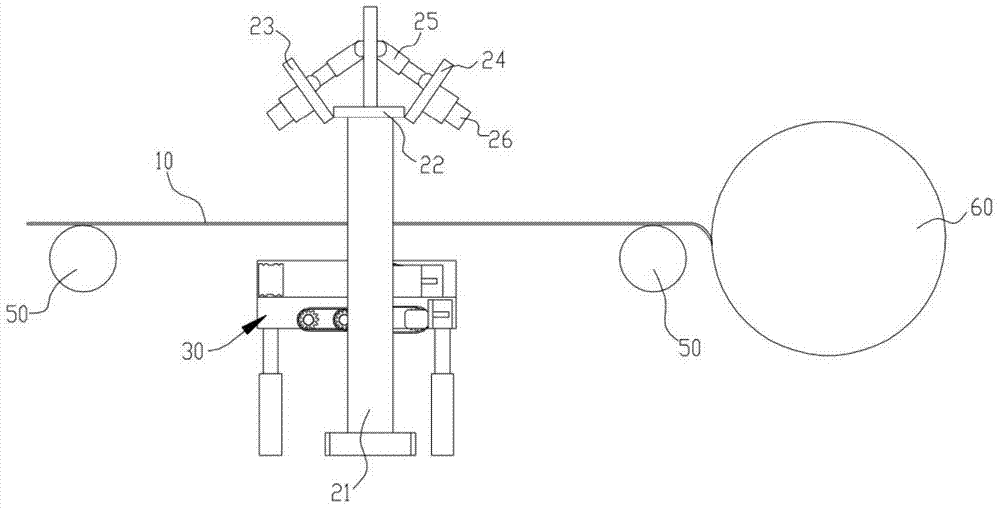

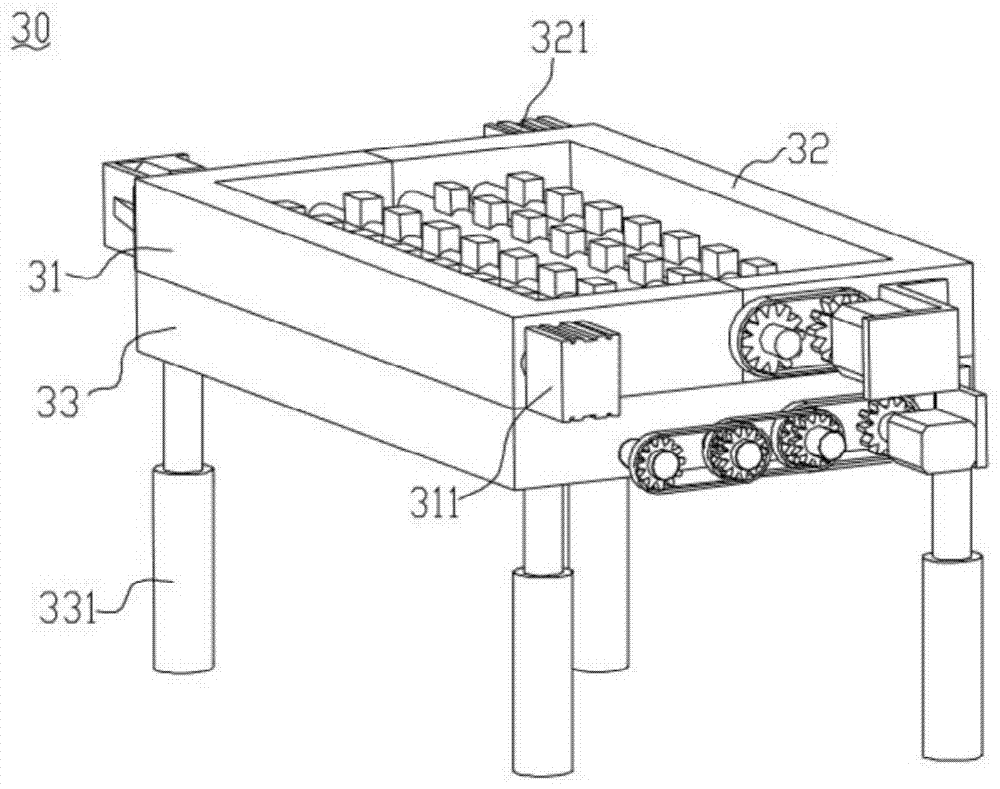

[0026] like figure 1 and figure 2 As shown, the present invention provides an on-line abnormality early warning control device for non-woven fibers, including: a web 10, a camera unit 20, a light source frame unit 30, a light source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com