A real-time automatic counting method of production line output

An automatic counting and production line technology, applied in the direction of counting mechanism/articles, instruments, etc., can solve the problems of measurement error, loss of enterprise benefit, complex computer vision image detection equipment, etc., to achieve small error, fast statistical speed, low maintenance cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0026] Such as figure 1 As shown, the automatic counting device of the real-time output of the production line of the present invention includes a laser ranging sensor and an industrial control computer; the laser ranging sensor is installed on one side of the roller table, and the industrial control computer receives and analyzes the laser ranging sensor signal; the laser ranging sensor One or two sensors.

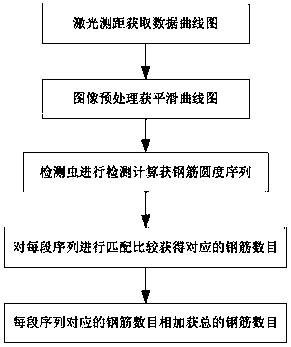

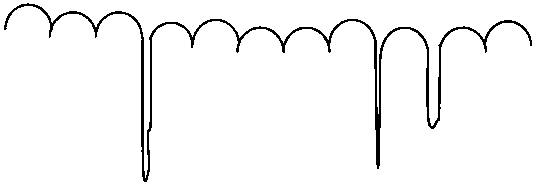

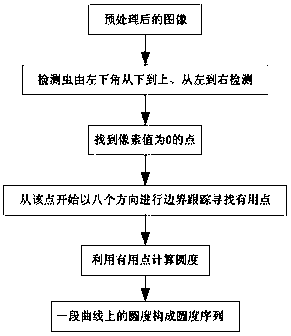

[0027] Such as figure 2 and image 3 Shown, the automatic counting method of a kind of production line real-time output of the present invention comprises the following steps:

[0028] A. Obtain the laser ranging data curve (such as image 3 shown);

[0029] B. According to the graph obtained by the laser ranging sensor, apply the image processing method to perform smoothing;

[0030] C. The detection insects are detected and calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com