A pear syrup candy and a preparation method thereof

A technology of pear jelly candy and pear juice, which is applied in the field of pear jelly candy and its preparation, can solve the problems of difficult industrial production, narrow application range, and many process steps, and achieve the effect of low cost, high quality, sweet and delicious taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

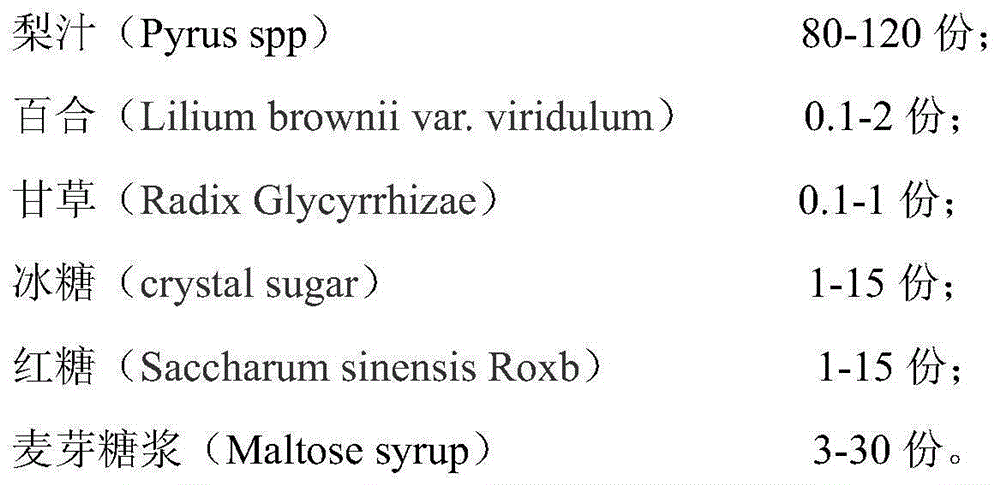

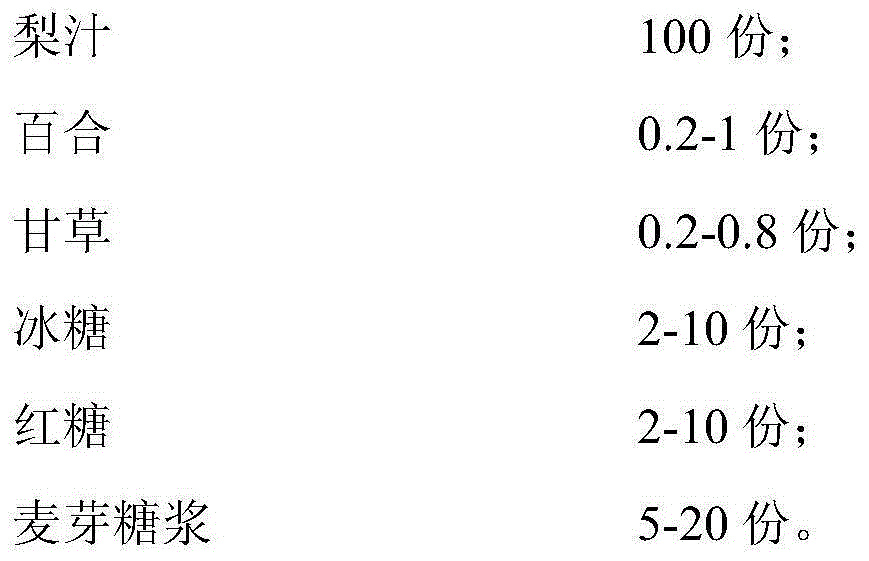

Method used

Image

Examples

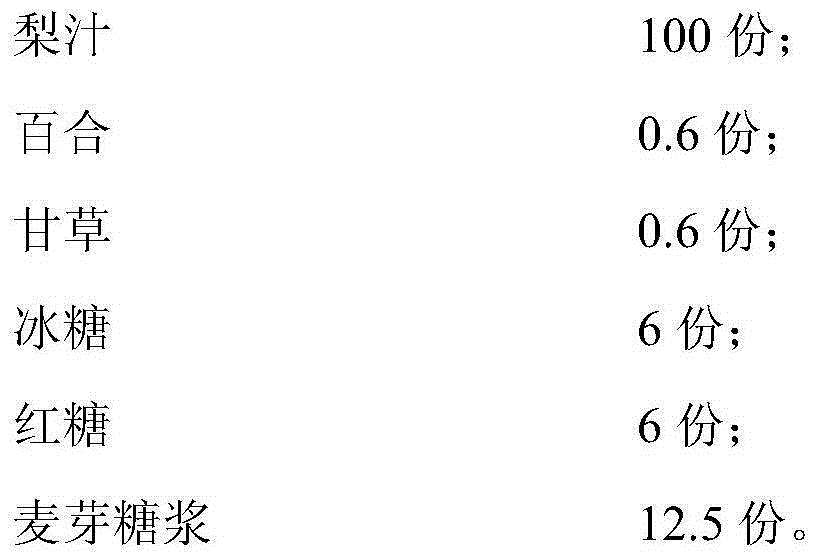

Embodiment 1

[0036] Take the pears and clean them, squeeze the juice, then boil for the first time, cool, settle, and filter. The boiling temperature is 1750°C for 3.5 hours. Take 100g of filtered pear juice, add 0.6g of lily, 0.6g of licorice, 6g of rock sugar, 6g of brown sugar, and 12.5g of malt syrup, mix and then boil for the second time, cool, settle, collect juice, and boil The temperature was 850°C and the time was 3.5 hours. That is, pear paste candy sample 1#.

Embodiment 2

[0038] Take the pears and clean them, squeeze the juice, then boil for the first time, cool, settle, and filter. The boiling temperature is 1300° C. for 5 hours. Take 100g of filtered pure pear juice, then add 0.2g of lily, 0.2g of licorice, 2g of rock sugar, 2g of brown sugar, and 5g of malt syrup, mix and then boil for the second time, then cool, settle, and collect the juice. 500°C for 5 hours. That is, pear paste candy sample 2#.

Embodiment 3

[0040] Take the pears and clean them, squeeze the juice, then boil for the first time, cool, settle, and filter. The boiling temperature is 2200° C. for 2 hours. Take 100g of filtered pure pear juice, then add 1g of lily, 0.8g of licorice, 10g of rock sugar, 10g of brown sugar, and 20g of malt syrup, mix and then boil for the second time, then cool, settle, and collect the juice. The boiling temperature is 1200°C for 2 hours. That is, pear paste candy sample 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com