Spiral-flow type flue gas dedusting and demisting device

A demisting device and swirl-type technology, which is applied in the field of flue gas purification, can solve the problems of high cost, high operating cost, and low enthusiasm for wet electrostatic precipitators, and achieve the effect of low cost, low operating cost, and easy large-scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

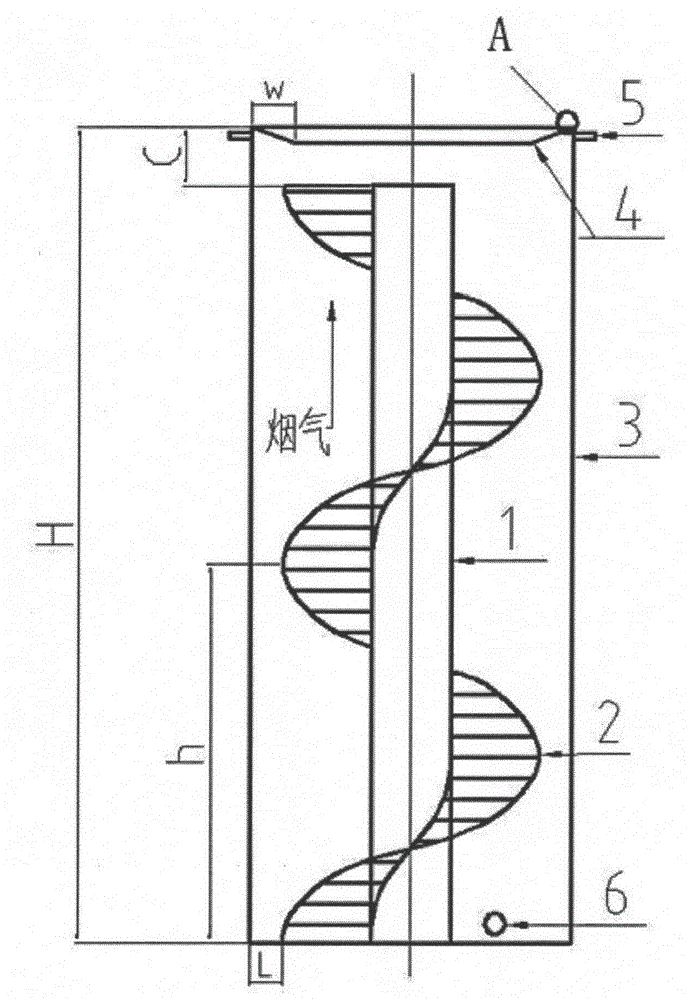

[0033] as attached figure 2 As shown, the original flue gas enters from the inlet flue 7 at the bottom of the absorption tower 9, and reacts in countercurrent contact with the limestone-gypsum slurry sprayed down from the spray layer 10, and then the flue gas carries a large number of droplets with a diameter of 1 to 1000 μm and Dust leaves the top of the spray layer and enters the swirling flue gas dust and mist removal device 11 of the present invention at a speed of about 4 m / s, and the purified flue gas leaves the absorption tower 9 through the outlet flue 12 .

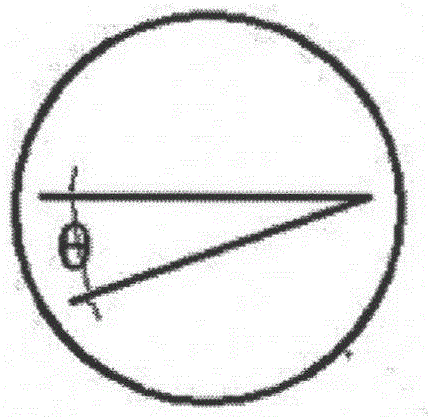

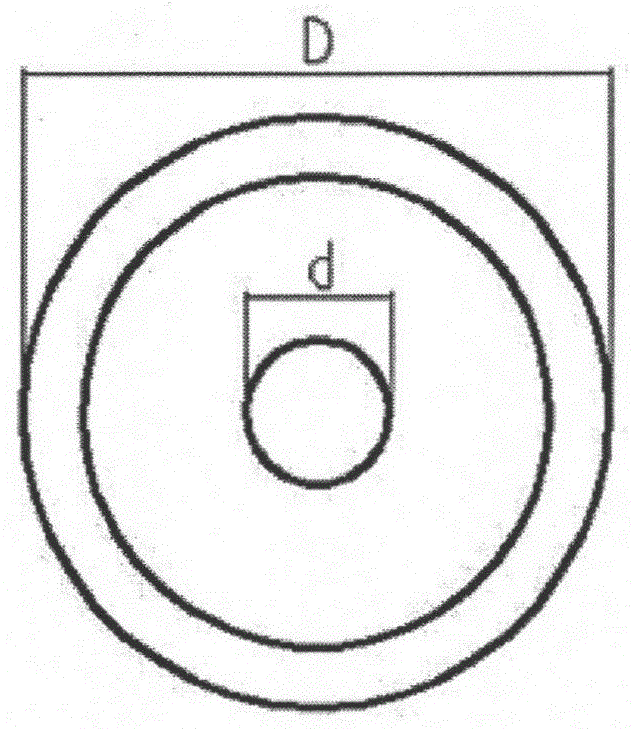

[0034] Between the top of the spray layer and the outlet of the absorption tower, 3 layers of cyclone type flue gas dedusting and demisting devices 11 of the present invention are arranged, the layer spacing is 1.2m, the total height of each layer of devices H=60cm, diameter D=20cm, support rod The diameter is d=4cm, the distance between the swirl sheet and the wall is L=1cm, and the height difference between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com