Electrostatic water washing dust removing apparatus

A water washing dust removal and static electricity technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of difficult to filter small particles of dust, the filter cannot be recycled, and the ventilation efficiency is reduced, so as to achieve good dust removal effect, reduce the content of adsorbable particles, and prolong the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

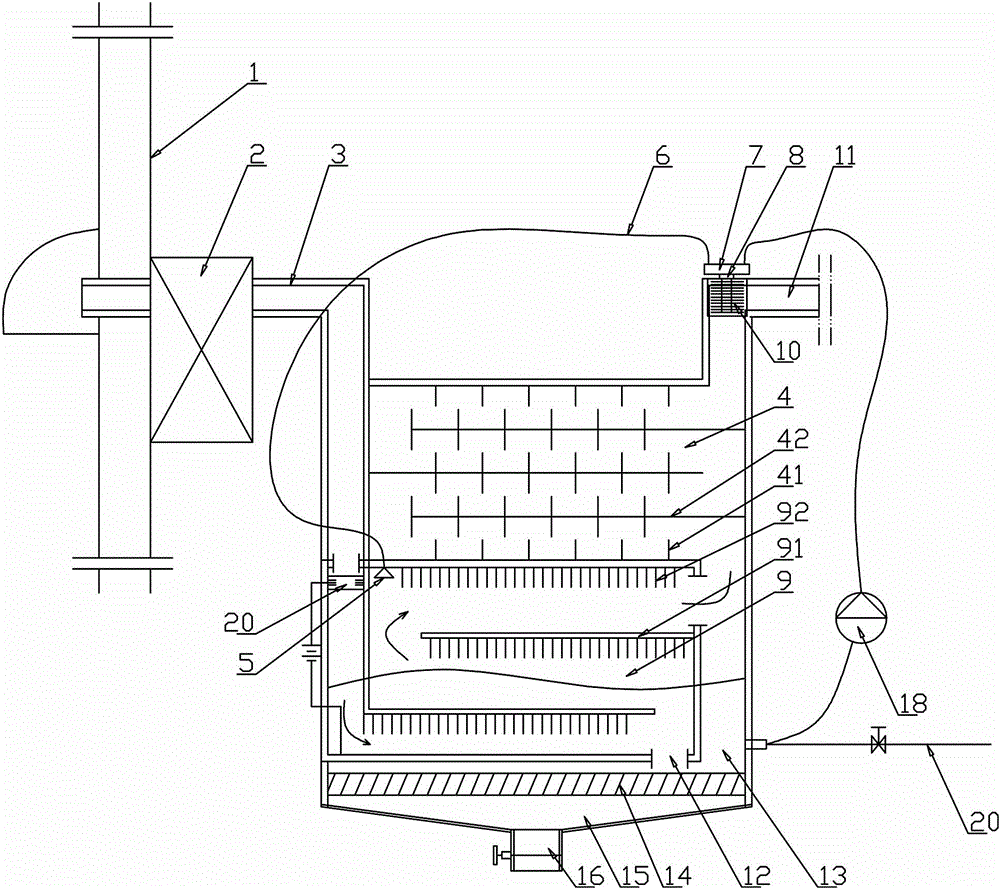

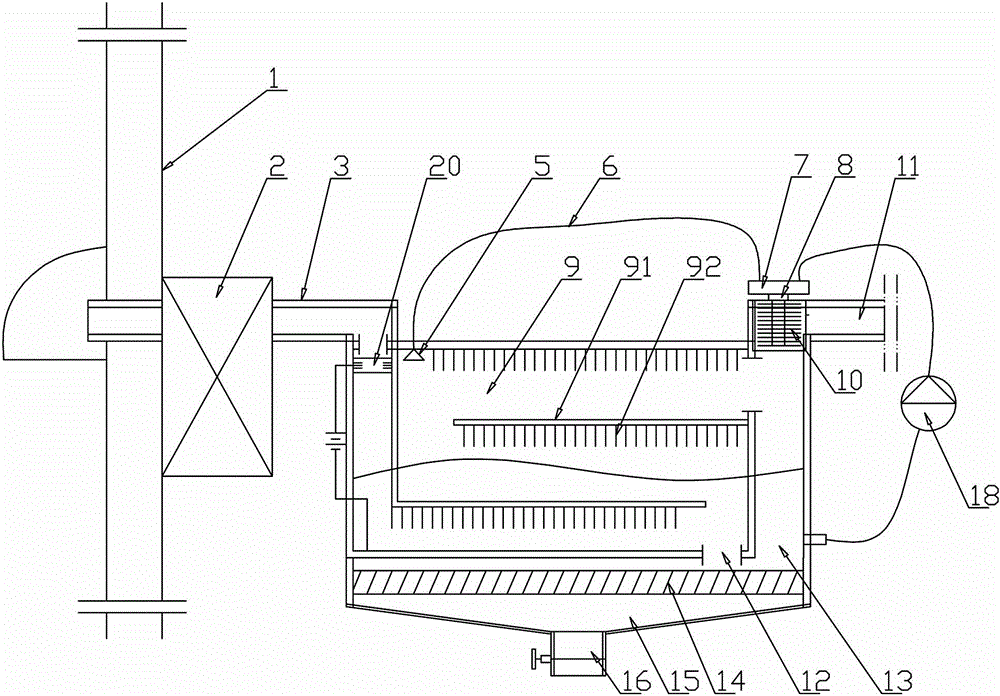

[0029] like figure 2 Among them, an electrostatic water washing and dust removal device includes a casing 17, and an air intake pipe 3 and an exhaust pipe 11 are arranged on the casing 17, and the air intake pipe 3 or the exhaust pipe 11 is connected with the fresh air blower 2; .

[0030] A liquid phase labyrinth 9 is provided in the housing 17, the air inlet of the liquid phase labyrinth 9 is communicated with the air intake pipe 3, and the air outlet is communicated with the exhaust pipe 11;

[0031] Said liquid phase labyrinth 9 is at least partially submerged in the liquid. With this structure, the exchange path between air and water is extended, and the dust removal effect is improved.

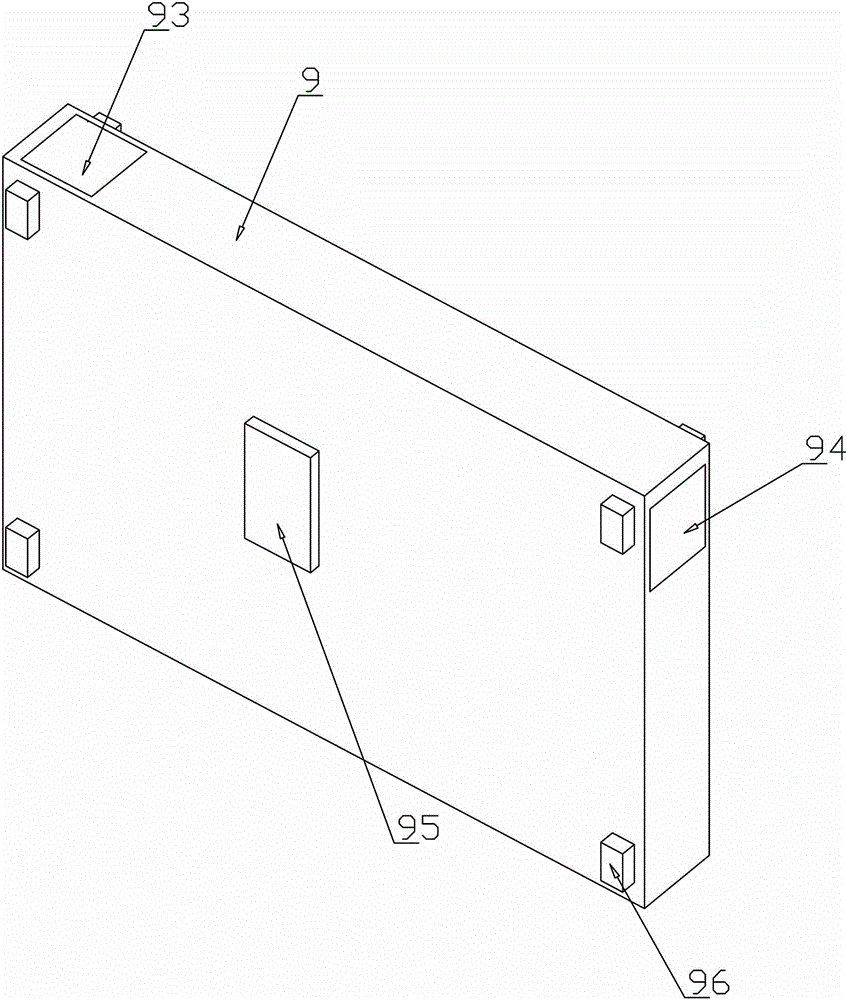

[0032] An optimized solution such as figure 2 Among them, the liquid phase labyrinth 9 is formed by a plurality of horizontally arranged partitions 91 staggered, and at least the water-facing surface of the partitions 91 is provided with a bristle layer 92 . With the bristle layers...

Embodiment 2

[0043] On the basis of Example 1, the further optimized structure is as figure 1 As shown in, a gas phase labyrinth 4 is also provided, the inlet of the gas phase labyrinth 4 is connected with the gas outlet of the liquid phase labyrinth 9, and the outlet of the gas phase labyrinth 4 is communicated with the exhaust pipe 11;

[0044] In the gas phase labyrinth 4, a plurality of horizontal partitions 42 are staggered to form a first-level labyrinth, and a plurality of vertical partitions 41 are staggered to form a second-level labyrinth. At least between the horizontal partitions 42 and the vertical partitions 41 An adsorption layer is provided on the windward side. This structure realizes the supplementary adsorption of particulate matter in the air, and at the same time helps to reduce the liquid droplets in the air, thereby reducing the humidity of the air outlet, and this structure also reduces wind resistance. The absorbent layer in this example can adopt the fabric with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com