Environmental protection type exhaust gas purification equipment high in purification efficiency

A technology for purification and purification efficiency of waste gas, applied in chemical instruments and methods, separation methods, separation of dispersed particles, etc., can solve problems such as inability to purify waste gas, gas containing harmful substances, and general effects, and achieve high purification efficiency, environmental protection, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

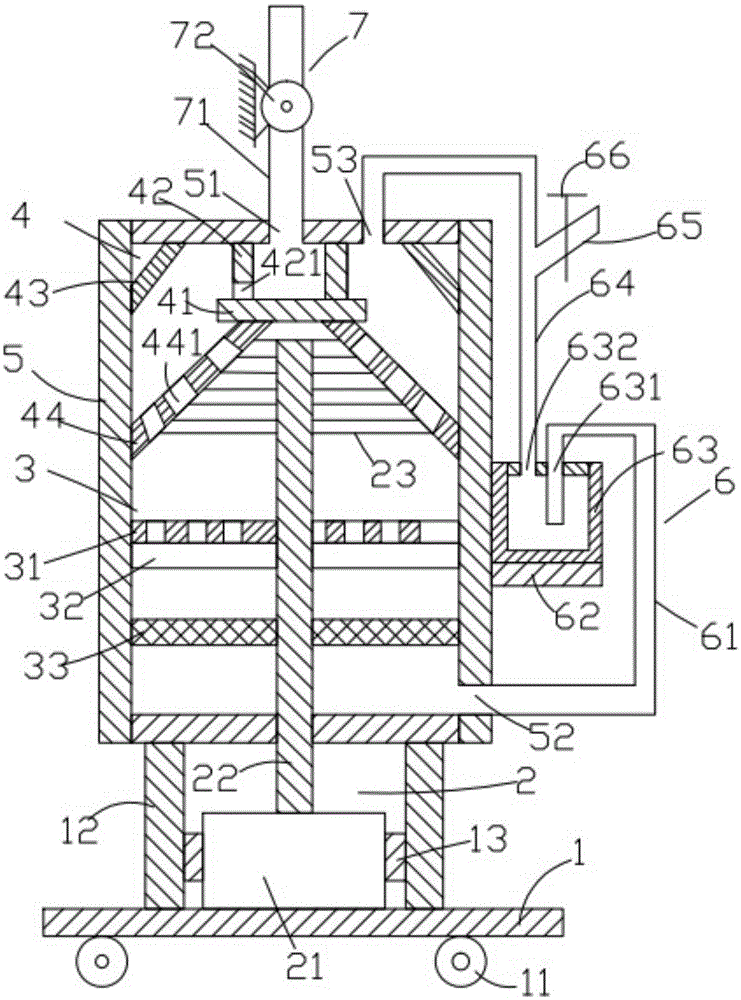

[0020] Such as figure 1 As shown, the environment-friendly exhaust gas purification equipment with high purification efficiency of the present invention includes a base 1, a rotating device 2 located above the base 1, a frame 5 located above the rotating device 2, and a first filter located inside the frame 5. The device 3 , the second filtering device 4 inside the frame body 5 , the water purification device 6 on the right side of the frame body 5 , and the air intake device 7 above the frame body 5 .

[0021] Such as figure 1 As shown, the base 1 includes a universal wheel 11 located on the lower surface of the base 1, a first support column 12 located between the base 1 and the frame body 5, and a first support column 12 located between the first support column 12. The positioning block 13 between, the base 1 is a cuboid, the base 1 is placed horizontally, the universal wheels 11 are provided with several, the universal wheels 11 are arranged on the lower surface of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com