Electrified water washing device and method

A technology of flushing device and charged water, which is used in the field of flushing outdoor insulation facilities of substation equipment and flushing equipment with charged water, can solve the problems of high labor intensity, electric shock accidents, and difficulty in guaranteeing, and achieves good cleaning effect, good versatility, and operation. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

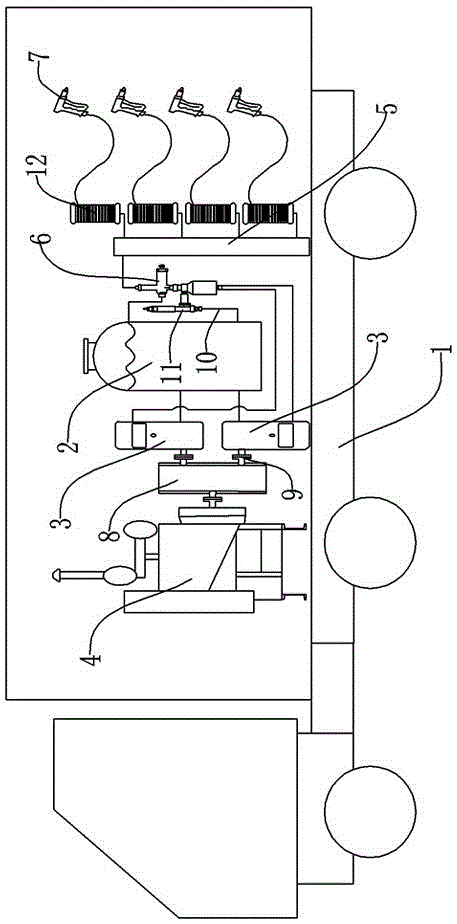

[0018] A charged water flushing device such as figure 1 , comprising a walking trolley 1, an ultrapure water tank 2 arranged on the walking trolley, a water pump, and an engine 4 for driving the water pump; the inlet pipeline of the water pump communicates with the ultrapure water tank, and its outlet pipeline communicates with the inlet of the bus bar 5 , a pressure regulating device 6 is arranged on the outlet pipeline of the water pump, and a plurality of outlet branch pipes are arranged on the busbar, and each outlet branch pipe is connected to the high-pressure spray gun 7 through the pipeline respectively.

[0019] The water pump connected to the ultrapure water tank 2 of the charged water flushing device can be a plunger pump 3, which not only has high efficiency and energy saving, but also can adjust the flow rate by using the displacement. Two plunger pumps 3 can be provided, connected in parallel, driven by the engine through two output shafts 9 of the transfer case ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com