Grinding robot platform

A technology of robots and robot arms, which is applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., and can solve the problems of insufficient rotation angle, not very wide application range, unstable robot arm movements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the improvement made by the present invention compared with the prior art, the specific embodiments of the present invention will be described in detail below.

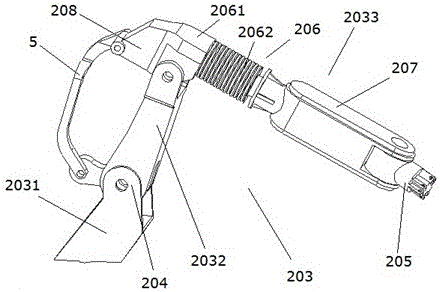

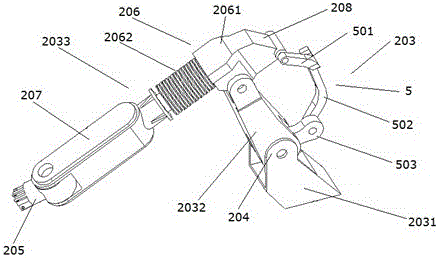

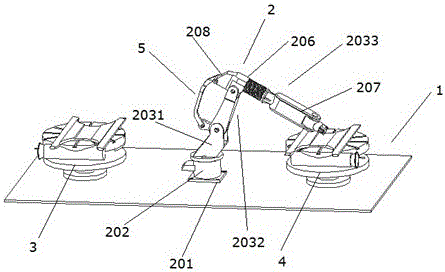

[0036] Such as figure 1 , 2As shown, the rotating arm 203 of the 360-degree full-circumferential rotating robot arm 2 of the present invention, the rotating arm 203 includes a first shaft arm 2031, a second shaft arm 2032 and a third shaft arm 2033; The arm 2031 has an ear seat 204 for installing the second shaft arm 2032; the bottom end of the first shaft arm 2031 is equipped with a 360-degree full-circumferential rotation shaft; the second shaft arm 2032 and the third shaft arm 2033 One end of the third shaft arm 2033 is movably connected, and the other end of the third shaft arm 2033 is equipped with a grinding head member 205 .

[0037] The third shaft arm 2033 is composed of a telescopic rod 206 and a connecting rod 207; the grinding head member 205 is installed on the conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com