Welding coil spring mounting tool

A technology for installing tools and coil springs, which is applied in the direction of manufacturing tools and hand-held tools, etc., can solve the problems of high equipment cost, complex configuration, and inability to meet the needs of the middle and low-end welding market, and achieve the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

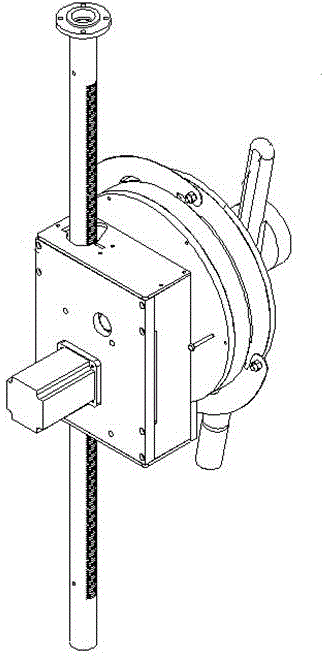

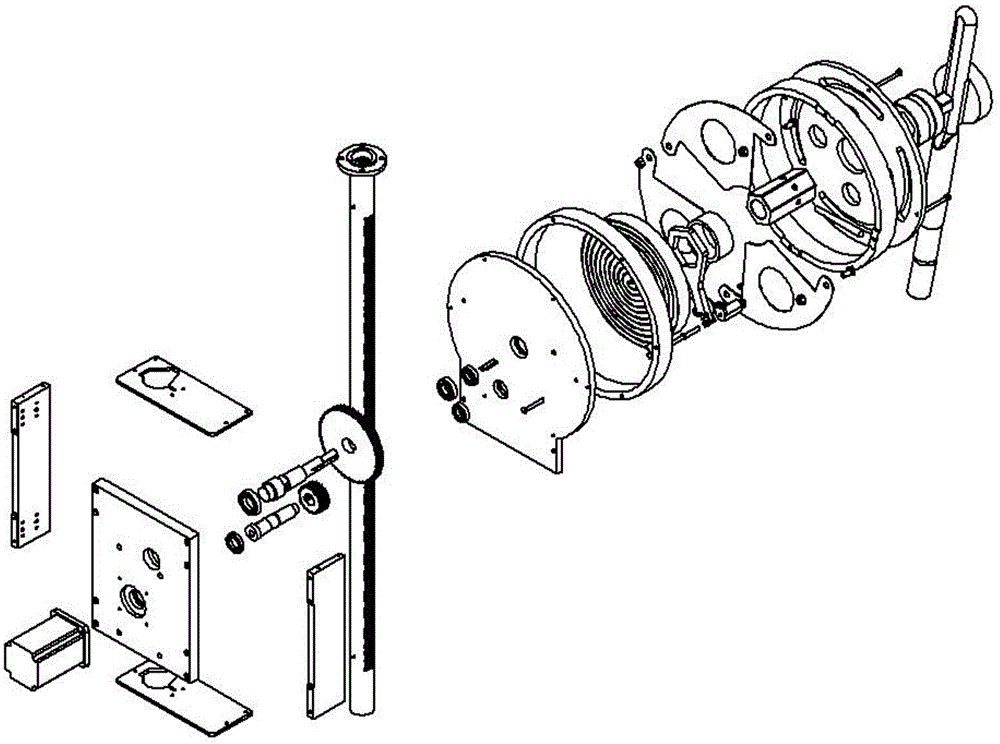

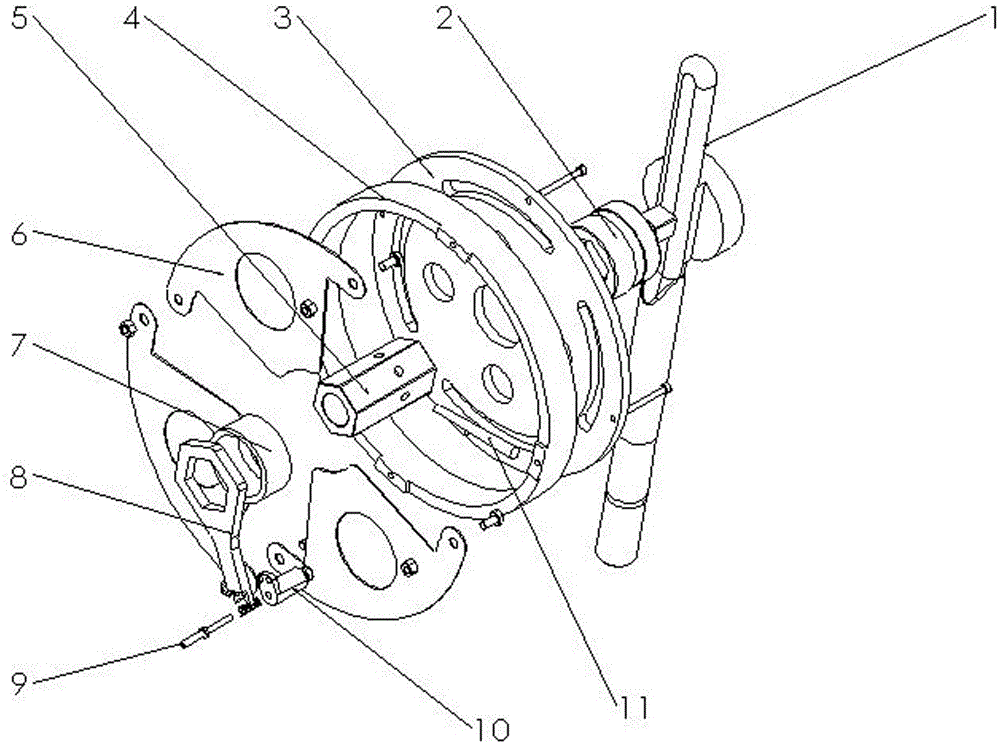

[0019] see Figure 1-Figure 4 , in the embodiment of the present invention, the welding coil spring installation tool includes a torque wrench 1, a rotating shaft 2, a front cover 3, a front box cover 4, a hexagonal rotating shaft 5, a coil spring cover 6, a sleeve 7, a hexagonal Shaped rotary clip 8, bolt holder 9, bolt holder 10, cylinder insert 11. The cylindrical insert 11 is connected with the coil spring 12, the bolt holder 10 is connected with the bolt holder 9, the bolt holder 10 is connected with the hexagonal rotating clamp 8, and the hexagonal rotating shaft 5 is fastened The screw is connected with the torque wrench 1, and at the same time, the hexagonal rotating shaft 5 is inserted into the hexagonal rotating clamp 8; the tightening degree of the coil spring 12 is controlled by turning the torque wrench 1 and the value on the torque wrench.

[0020] The simple welding robot vertical shaft includes a coil spring 12, a front end baffle ring 13, a front end baffle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com