How to make insulation blocks

A technology for thermal insulation blocks and manufacturing methods, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., and can solve the problems affecting the integrity of blocks, compression resistance, shear resistance, thermal insulation performance, unreliable connection between thermal insulation structure and skeleton, and cumbersome production process and other problems to achieve the effect of solving unreliable connection, simple and clear production process, and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

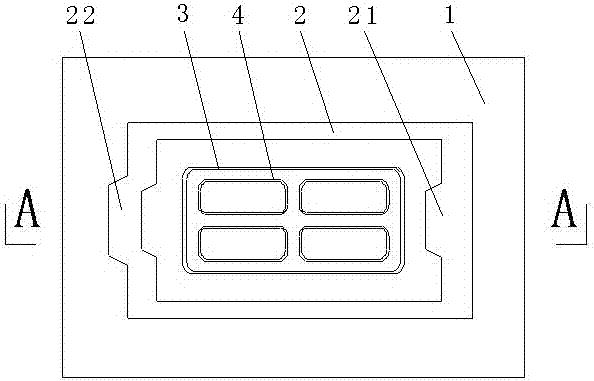

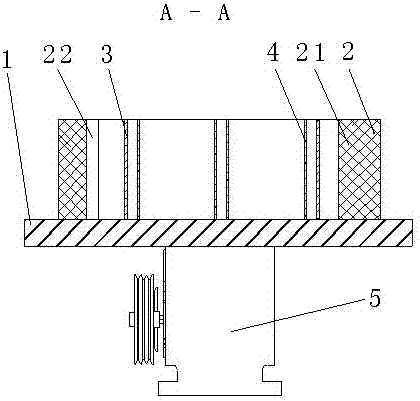

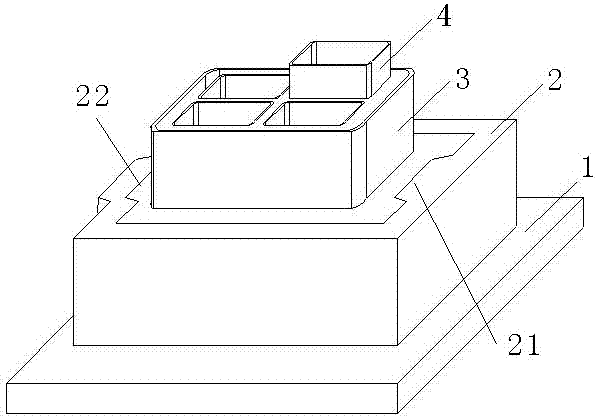

[0020] like Figure 1 to Figure 5 The shown thermal insulation block and its production device include a base 1, a back-shaped outer mold frame 2 is placed above the base 1, and a protrusion 21 is provided on one side of the inner side of the outer mold frame 2. The outer frame 2 is provided with a recess 22 on the inner side opposite to the protrusion 21, and the shape and size of the recess 22 are the same as those of the protrusion 21; The back-shaped inner mold frame 3, the side of the inner mold frame 3 is parallel to the side of the outer mold frame 2, and the inner mold frame 3 is provided with four identical back-shaped core mold frames 4 placed on the base 1 , the gap between the outer wall of the mandrel frame 4 and the inner wall of the inner mold frame 3 forms a square shape, and a vibrating device 5 is provided below the base 1 . A kind of thermal insulation block prepared by the present invention, the thermal insulation block includes a square-shaped skeleton 7,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com