Sealed Z-type corrugated edge belt conveyor

A belt conveyor and corrugated technology, applied in the field of sealed Z-type corrugated sidewall belt conveyor, can solve the problems of inability to achieve horizontal conveying, inability to achieve vertical lifting, increase equipment cost, etc., to reduce the workload of operation and maintenance, and to achieve superior performance. , the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

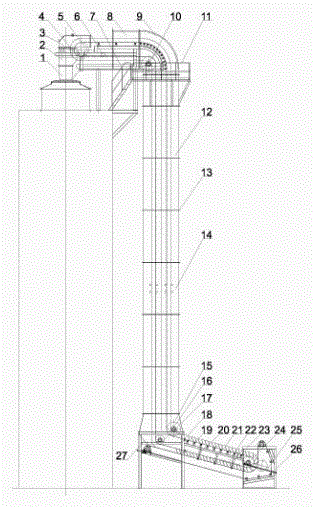

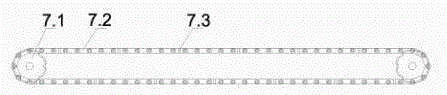

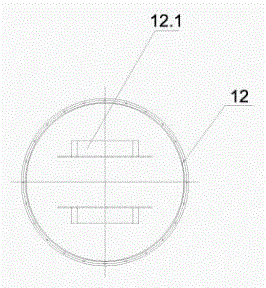

[0030] Such as Figure 1~Figure 5 As shown, the sealed Z-shaped corrugated side belt conveyor includes the upper part: connecting chute 1, funnel 2, head cover 3, driving drum 4, head frame 5, vibrating cleaner 6, residual material cleaning device 7, upper part Horizontal section casing 8, inspection section casing 9, upper reversing drum 10, inspection platform 11. Located in the middle: the vertical section intermediate housing 12 , the coupling piece 13 , the guide housing 14 , the coupling housing 15 , and the pinch roller 16 . Located in the lower part: the lower inclined section shell, the lower redirecting roller 17, the frame 18, the single upper idler roller 19, the single lower idler roller 20, the sidewall tape 21, the empty section cleaner 22, the tailstock 23, the tail Reversing drum 24, screw tensioning device 25, return material recovery device 26, surplus material guide trough 27. Among them: the upper horizontal section shell 8, the vertical section intermed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com