Charging cylinder for Ausmelt furnace

An Osmelt furnace and feeding tube technology, applied in furnaces, electric furnaces, rotary drum furnaces, etc., can solve the problems of easy bonding of the wall of the feeding tube, unfavorable flue gas treatment, and easy deformation of the feeding tube at high temperature, to achieve Effects of lowering temperature, preventing sticking, and reducing cleaning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

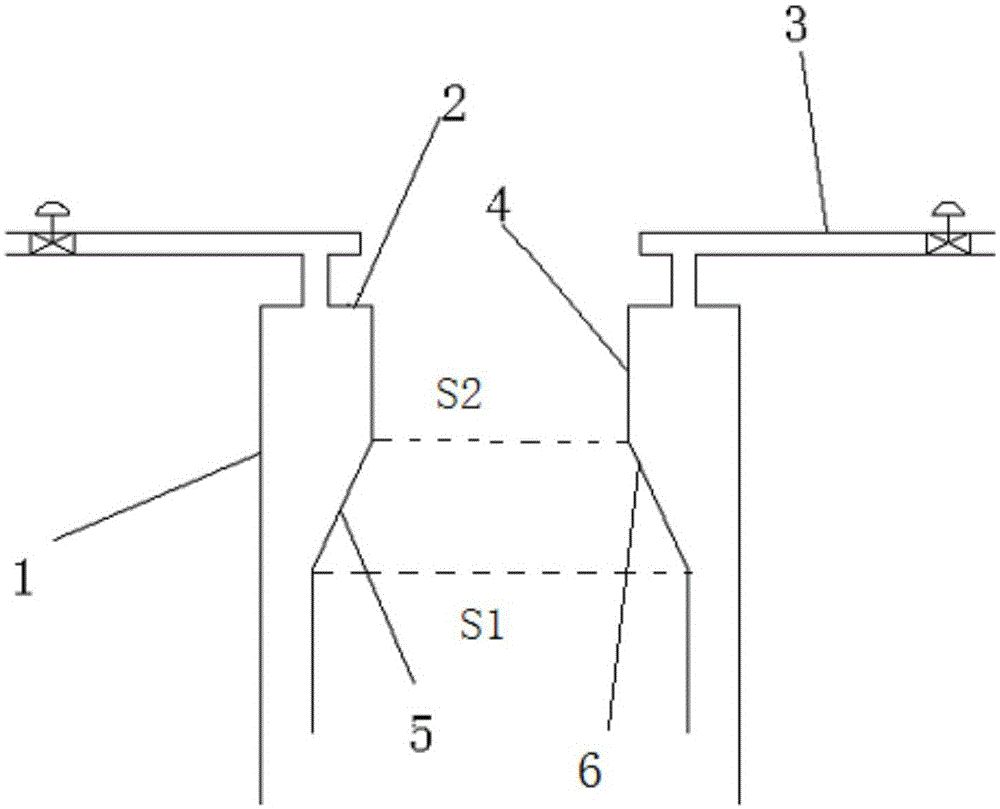

[0023] Example 1: Feeding cylinder for Osmert furnace, the opening of the feeding cylinder 1 is smaller than the feeding channel of the feeding cylinder 1, and the opening of the feeding cylinder 1 and the feeding channel are transitioned through the inclined plate 5, the opening of the feeding cylinder 1 The air supply pipe 3 is provided at the place.

[0024] A baffle 6 is symmetrically fixed at the opening of the feeding barrel 1 and extends into the feeding barrel 1. The baffle 6 is composed of a partition plate 2, a vertical plate 4, and an inclined plate 5.

[0025] The opening of the feeding cylinder 1 is provided with a stainless steel partition 2 with a thickness of 3 mm, and its size is 300 mm×450 mm, and the partition 2 and the feeding cylinder 1 are welded. The air supply pipe 3 arranged on the partition plate 2 is a metal hose, and the pipe diameter is DN32. One end of the vertical plate 4 is welded to the partition plate 2, and the other end of the vertical plate 4 i...

Example Embodiment

[0028] Example 2: A feeding cylinder for the Osmelt furnace, the opening of the feeding cylinder 1 is smaller than the feeding channel of the feeding cylinder 1, and the opening of the feeding cylinder 1 and the feeding channel are transitioned through the inclined plate 5, the opening of the feeding cylinder 1 The air supply pipe 3 is provided at the place.

[0029] A baffle 6 is symmetrically fixed at the opening of the feeding barrel 1 and extends into the feeding barrel 1. The baffle 6 is composed of a partition plate 2, a vertical plate 4, and an inclined plate 5.

[0030] The opening of the feeding cylinder 1 is provided with a stainless steel partition 2 with a thickness of 3 mm, and its size is 300 mm×450 mm, and the partition 2 and the feeding cylinder 1 are welded. The air supply pipe 3 on the partition plate 2 is a metal hose, and the pipe diameter is DN25. One end of the vertical plate 4 is welded to the partition plate 2, and the other end of the vertical plate 4 is c...

Example Embodiment

[0033] Example 3: Feeding cylinder for Osmelt furnace, the opening of the feeding cylinder 1 is smaller than the feeding channel of the feeding cylinder 1, and the transition between the opening of the feeding cylinder 1 and the feeding channel is through the inclined plate 5, the opening of the feeding cylinder 1 The air supply pipe 3 is provided at the place.

[0034] A baffle 6 is symmetrically fixed at the opening of the feeding barrel 1 and extends into the feeding barrel 1. The baffle 6 is composed of a partition plate 2, a vertical plate 4, and an inclined plate 5.

[0035] The opening of the feeding cylinder 1 is provided with a stainless steel partition 2 with a thickness of 5 mm, and its size specification is 250 mm×400 mm, and the partition 2 and the feeding cylinder 1 are welded. The air supply pipe 3 arranged on the partition plate 2 is a metal hose, and the pipe diameter is DN32. One end of the vertical plate 4 is welded to the partition plate 2, and the other end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com