Wheel-rail type loading and traveling cable crane

A cable-mounted crane and wheel-rail type technology, which is applied in the field of wheel-rail load traveling cable-mounted cranes, can solve the problems of economic decline, increase in the number of wire ropes, and increased economic investment, achieving significant economic benefits and ensuring safety Sexuality, the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

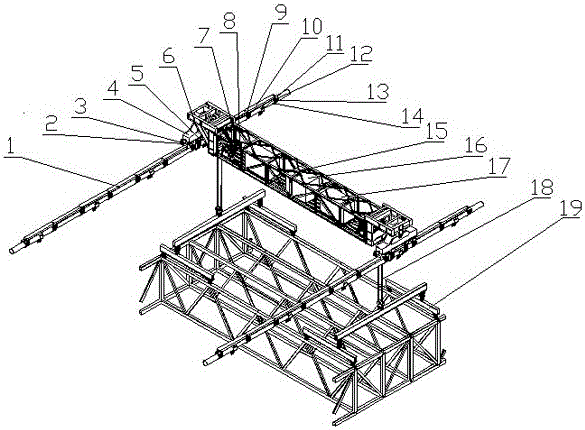

[0024] The specific implementation, structure, features and functions of the wheel-rail load-carrying cable-carried crane proposed according to the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

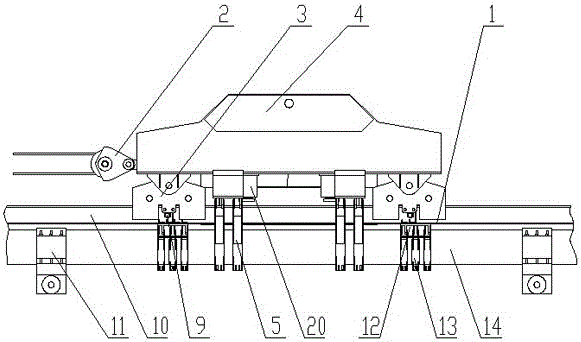

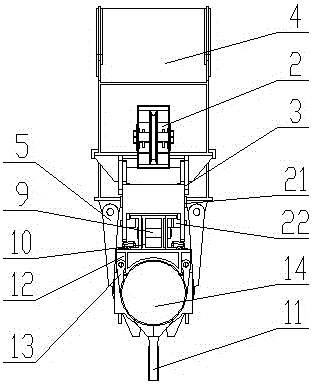

[0025] see Figure 1 to Figure 4 , the wheel-rail type load walking cable-carried crane of the present invention comprises a walking system 6, a lifting system 7, a control system 16, and a main truss structure 15, wherein: the walking system 6 is movably mounted on the walking guide rails 1 on both sides, The main truss structure 15 is connected between the walking systems 6, the winch 8 of the hoisting system 7 is arranged in the main truss structure 15, the lower part of the hoist 8 is connected with a spreader 19, and the main truss structure 15 is equipped with a control system 16 and an engine 17. The walking system 6 includes a walking mechanism main body 4, a tractor assembly 2, and a walking roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com