Electronic cigarette lighter for automobile

A technology for automotive electronics and cigarette lighters, applied to instruments, electrical components, incandescent ignition, etc., can solve the problems of short heating time, poor effect, and low conversion efficiency, and achieve reduced manufacturing costs, high transmission efficiency, and reduced surface area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

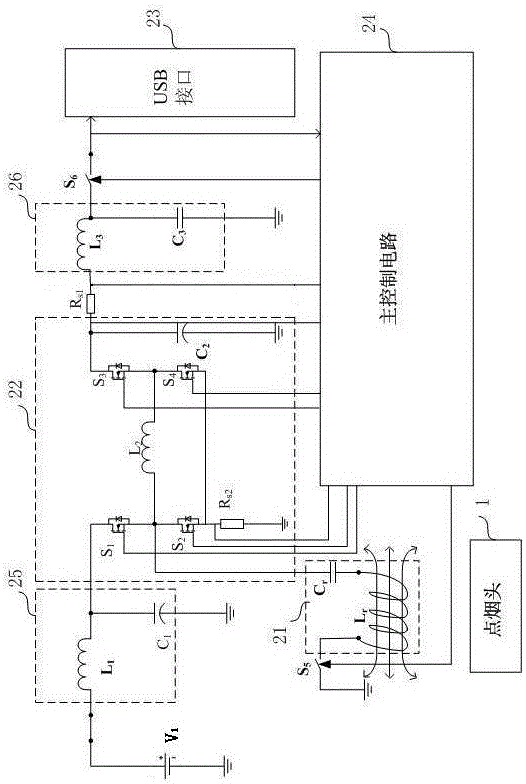

[0025] Please refer to figure 1 . According to an embodiment of the present invention, an electronic cigarette lighter for a car includes a cigarette lighting head 1 and a cigarette lighting and charging multiplexing circuit.

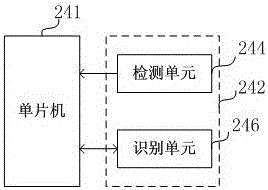

[0026] The cigarette lighter 1 is provided with a metal block. The cigarette lighting and charging multiplexing circuit includes an LC resonant circuit 21 , a synchronous rectification Buck-Boost circuit 22 , a USB interface 23 , a first switch circuit, a second switch circuit, an output current sampling circuit, a current-limiting current sampling circuit and a main control circuit 24 .

[0027] The LC resonant circuit includes a resonant capacitor C r and induction heating coil L r . exist figure 1 In the illustrated embodiment, the LC resonant circuit is an LC series resonant circuit. In another embodiment, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com