Central control wax boiling and drying equipment and its use method

A drying equipment and wax boiling technology, applied in local stirring dryers, lighting and heating equipment, dryers for stationary materials, etc. The effect of temperature control and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content, structural features, goals and effects of the present invention in detail, the following examples are given to describe the embodiments in detail with accompanying drawings.

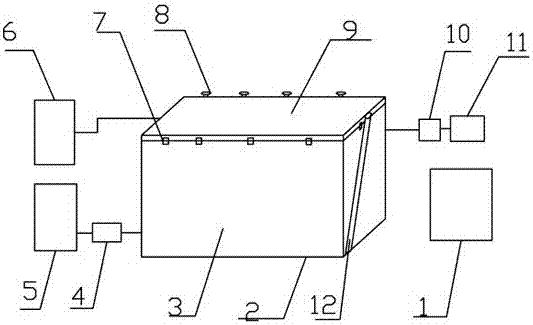

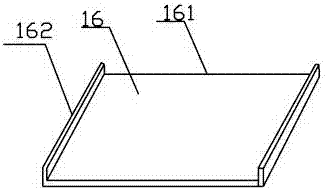

[0028] refer to Figure 1 to Figure 6 As shown, the central control wax boiling and drying equipment of the present invention includes a central control cabinet 1 and a wax boiling box 2, and the wax boiling box 2 includes a box cover 9 and a box body 3, and the box cover 9 and the box body 3 are connected by a hinge; the box body 3 and the box cover 9 are welded by steel plate 16 after the whole plate is bent, and reinforcing ribs are arranged on the steel plate 16; An insulating material 18 is provided between the panel 17 and the steel plate 16, and the steel plate 16 includes a bent edge 162 and a straight edge 161, and the bent edge 162 and the straight edge 161 of the side steel plate 16 of the box body 3 and the bottom surface steel plate 16 are b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com