A method for online detection of diesel engine stuffing box tightness

A detection method and stuffing box technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, etc., can solve the problems of power reduction, increased maintenance time of ships at ports, and excessive oil consumption. , to avoid misjudgment, improve work efficiency and economy, and improve self-diagnosis level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose and technical solutions of the embodiments of the present invention more clear, the technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings of the embodiments of the present invention.

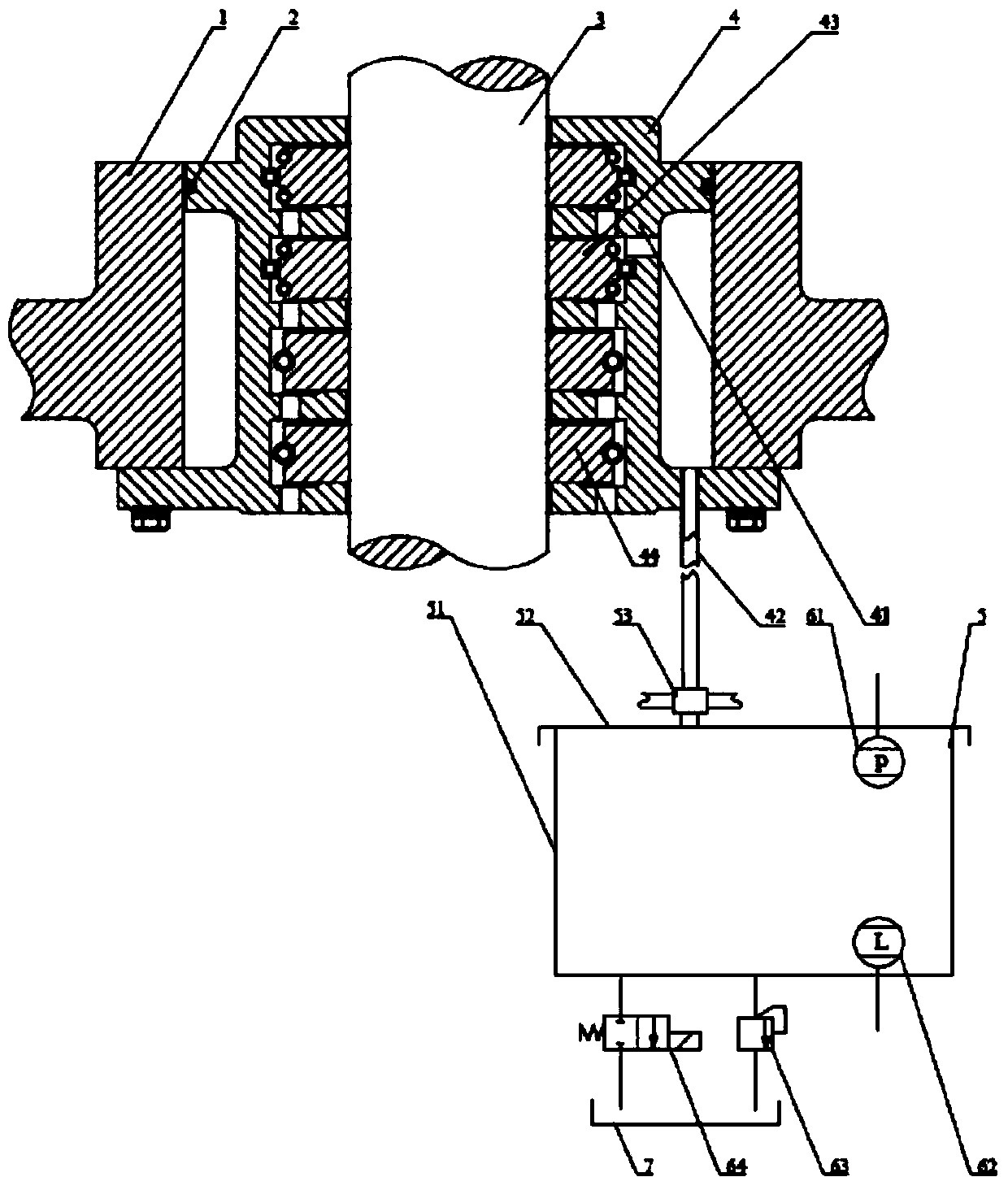

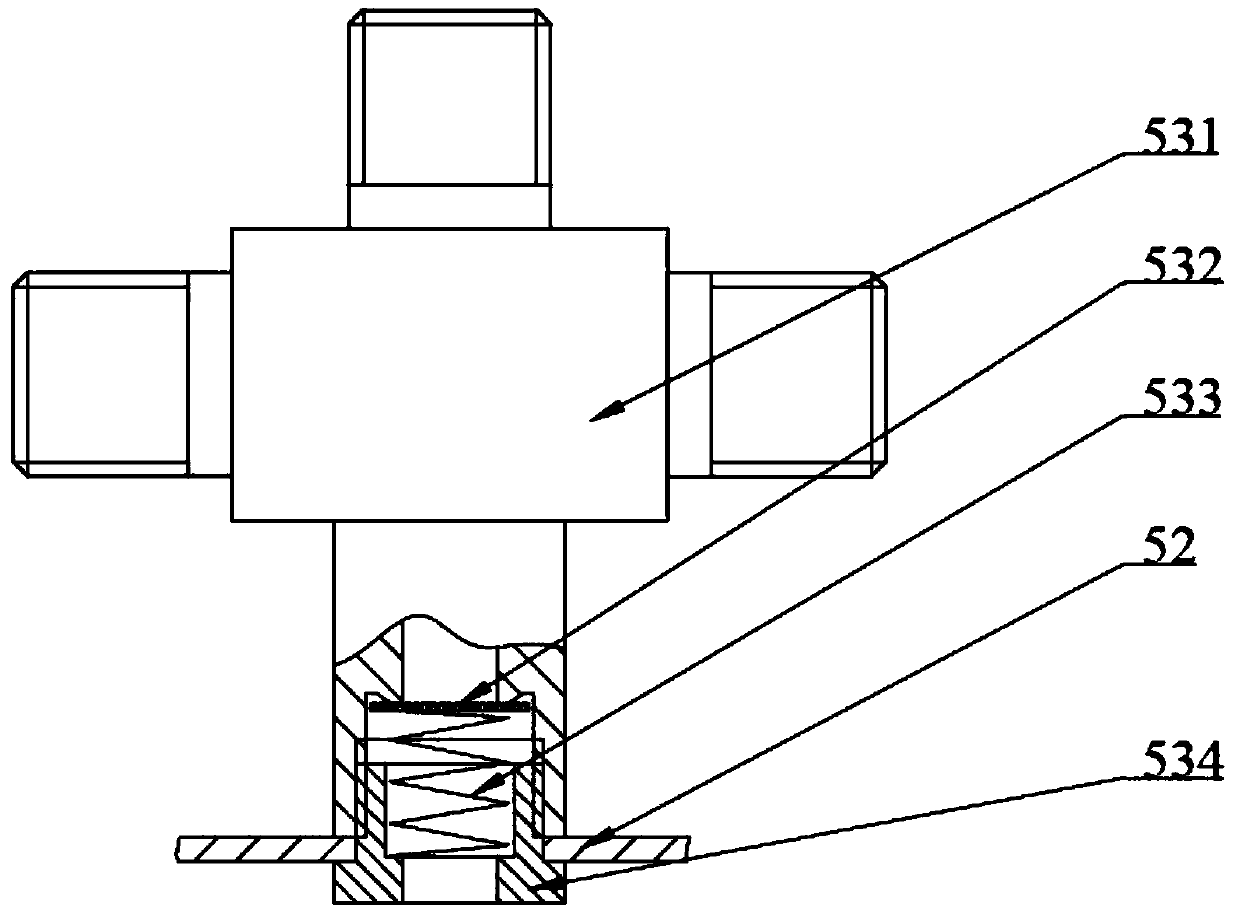

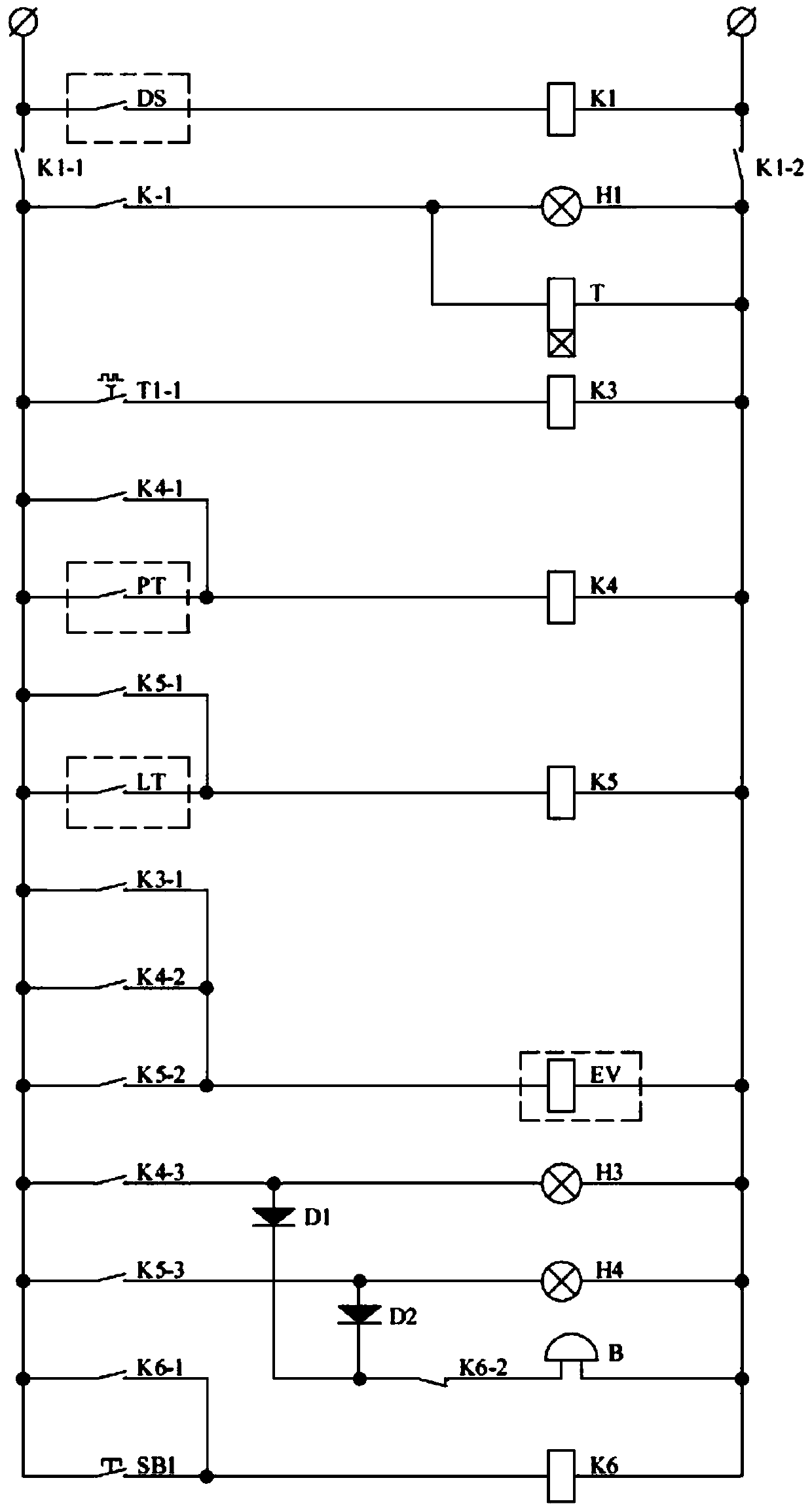

[0028] Such as figure 1 and 2 As shown, it is a kind of diesel engine stuffing box tightness detection device used in the online detection method of two-stroke diesel engine piston rod stuffing box tightness of the present invention, including a cylinder diaphragm installed in the body of the diesel engine and provided with a through hole 1. The stuffing box 4 and the external control box of the diesel engine body. The stuffing box 4 is centered with a small through hole at both ends and a large middle, and a cylindrical shape with a large flange at the lower end of the outer circle and a small flange at the upper end; The small flange is tightly connected with the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com