Freezing strength on-site fast detection device for backfill soil in frozen soil area

A detection device and backfill technology, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, etc., can solve the problems of distortion of measurement results, affecting the accuracy of detection results, and inapplicability of frozen backfill strength detection in cold regions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, the present invention is described in further detail:

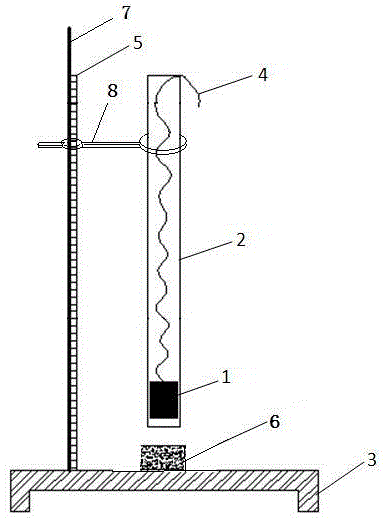

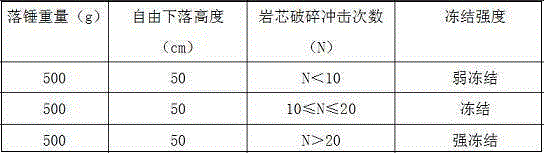

[0016] like figure 1 As shown, an on-site rapid detection device for the freezing strength of backfill soil in permafrost regions is mainly composed of a drop hammer 1, a guide groove 2, a backing plate 3, a traction line 4 and a scale 5, and the backing plate 3 is a thick steel plate, which can withstand repeated It is not easy to deform due to impact; the guide groove 2 is a smooth PE, or PVC pipe, or stainless steel pipe; the pulling wire 4 is a strong and soft thin wire. The drop hammer 1 is placed at the bottom of the guide groove 2, the traction line 4 connected with the drop hammer 1 is placed outside the guide groove 2, the scale 5 and the bracket 7 are fixed on the backing plate 3, and the bracket 7 has a fixing clip 8, and the fixing clip 8 clips Hold the guide groove 2, place the sample 6 on the backing plate 3, and the sample 6 is opposite to the guide gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross-sectional area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com