Portable insulation shielding fabric flaw testing method and testing instrument

A defect testing, portable technology, applied in the direction of testing dielectric strength, optical testing flaws/defects, etc., can solve the problems of no longer live work, no scientific measurement method, etc., achieve significant beneficial effects, suitable for application and promotion , precise positioning and detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

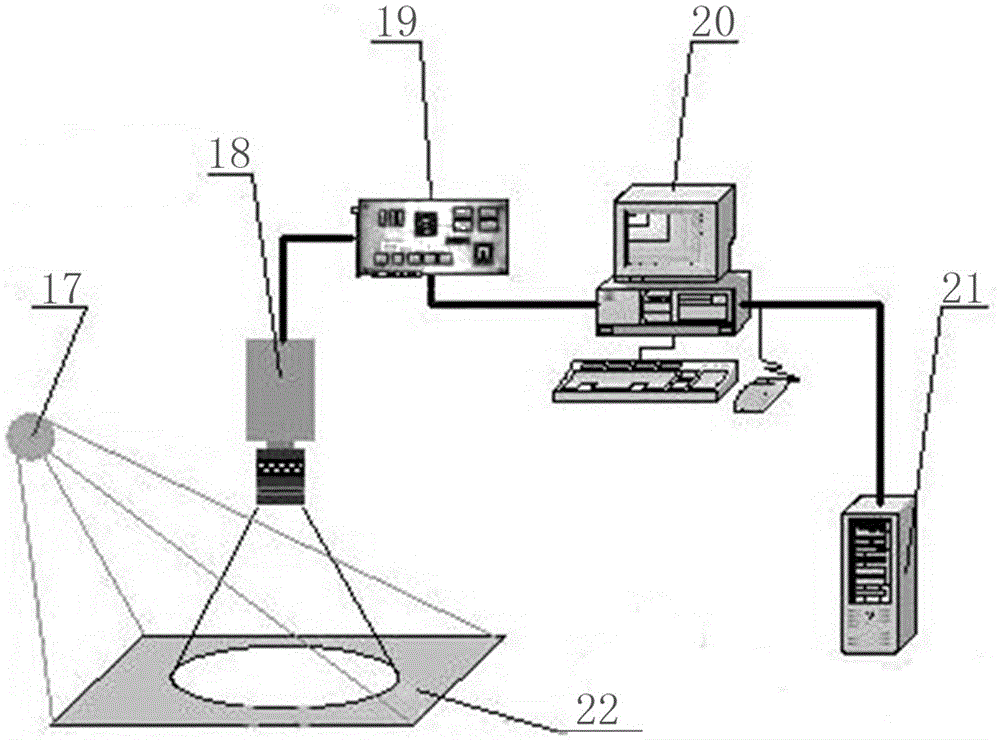

[0023] like figure 1 As shown, the schematic diagram of the existing image acquisition system is provided. The CCD camera 18 shown in the figure collects images of the detected target 22 under the illumination of the illumination system 17, and the collected images are processed by the image acquisition card 19. , forming image data that can be recognized by the industrial computer 20 . The industrial computer 20 can not only display the received images, but also perform processing, identification, etc., and feed back the processing results to the control mechanism 21, and perform corresponding operations through the control mechanism 21. It can be seen that the collection of high-definition images is a relatively mature technology.

[0024] The defect detection method of the portable insulating protective fabric of the present invention is as follows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com