Oxygen chemical sensor for high temperature and high pressure hydrothermal system and preparation method thereof

A high-temperature and high-pressure water and oxygen chemistry technology, applied in scientific instruments, instruments, measuring devices, etc., can solve the problems of low working temperature and pressure of chemical sensors, questioned reliability, slow response speed, etc., and achieves good thermochemical stability. Strong integrity and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

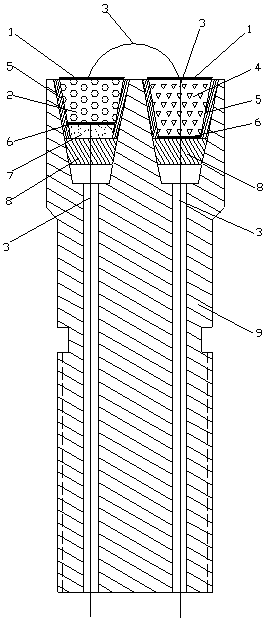

[0026] In order to make the purpose, technical scheme and advantages of the present invention clearer, the following will be combined with the attached figure 1 The present invention is further described in detail.

[0027] 1. Fabrication of various parts of the sensor. Such as figure 1 As shown, the parts of the electrode in this embodiment are mainly composed of base 9, truncated conical high temperature resistant insulating cone pad 8, solid oxygen buffer 7, high temperature resistant insulating cone sleeve 5, conical solid electrolyte ceramic 2, conical truncated high temperature resistant It is composed of insulating ceramics 4, sponge-like inert metal layer 1, inert metal sheet 6 and electrode leads 3, etc. Among them, the base 9 is made of a high-temperature nickel-based alloy, and one end of the nickel-based alloy base 9 has two taper holes, and the other end has two through holes connected with the taper holes; 8 and high-temperature-resistant insulating cone sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com