A method of gas hydrate solid-state fluidized mining excavation indoor experimental device

A technology of solid fluidized mining and gas hydrate, applied in the direction of material inspection products, fuel oil testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

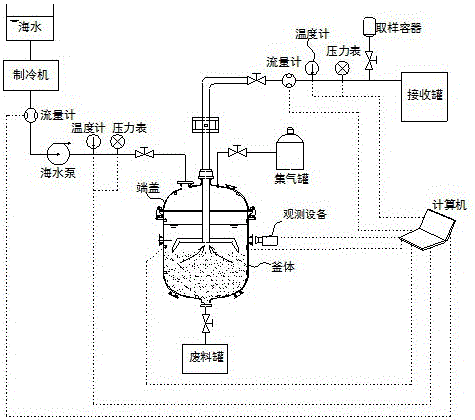

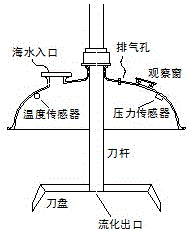

[0039] In this specific example, the simulation will describe in detail the mining, excavation and fluidized collection of natural gas hydrate in a water depth of 1500m with a seawater pressure of 15MPa and a fluidized seawater flow rate of up to 8L / s. The seawater injection device adopts a pump that can stably provide a seawater flow rate of 0-8L / s under various pressures of 0-15MPa as the main component. The flow, temperature and pressure are monitored by the pressure gauge, thermometer and flowmeter involved in the seawater injection device as auxiliary control components.

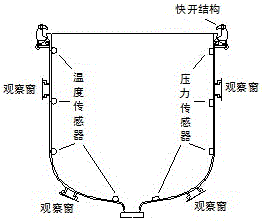

[0040] First, transfer the natural gas hydrate sediment sample prepared in the large sample preparation tank to the mining tank, and cover the upper end cover matching the lower tank body; then inject cooled cold seawater, keep the temperature and pressure constant to simulate Real seabed temperature and pressure conditions.

[0041] Move the prepared natural gas hydrate sediment samples to the mining ...

specific Embodiment 2

[0048] On the basis of specific embodiment 1, after the crushing of natural gas hydrate sediment particles begins, monitoring the temperature and pressure changes in the kettle body, the phase state changes of natural gas hydrate and the particle size distribution of sediment particles during the crushing process , collect a small amount of fluidized material samples during the fluidization process, and analyze the content of each phase and particle size distribution.

[0049] First, the sampling container is evacuated. During fluidization, the valve connecting the sampling container and the fluidization pipeline is closed. After the fluidization starts, the valve can be opened at any time to obtain a sample of hydrate fluidization. The samples are mainly used for the test of particle size distribution, air content and single-phase ratio of slurry.

specific Embodiment 3

[0050] On the basis of specific embodiment 1 and specific embodiment 2, it also includes a waste pipe connected to the bottom of the excavation tank through a second valve. After the experiment is completed, open the valve connected to the waste tank to collect the hydrate deposits and seawater involved in the tank.

[0051] The implementation scheme of the patent application of the present invention combines the experimental simulation of the experimental process with the numerical simulation, and solves the key technical problems of the excavation and fluidization modules in the solid fluidization mining process of natural gas hydrate in the shallow surface layer of the seabed. The experimental device can be used to analyze the phase state change of natural gas hydrate during mechanical crushing, the influence of different crushing methods on phase state change, the particle size distribution of natural gas hydrate particles under different mechanical crushing conditions, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com