Cage-style spherical split reflector universal adjusting structure

A technology for adjusting structure and mirrors, applied in installation, optics, instruments, etc., can solve the problems of poor anti-vibration ability of adjusting structure, waste of optical product resources, long debugging period, etc., to avoid crosstalk of different degrees of freedom and anti-vibration effect. Good, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

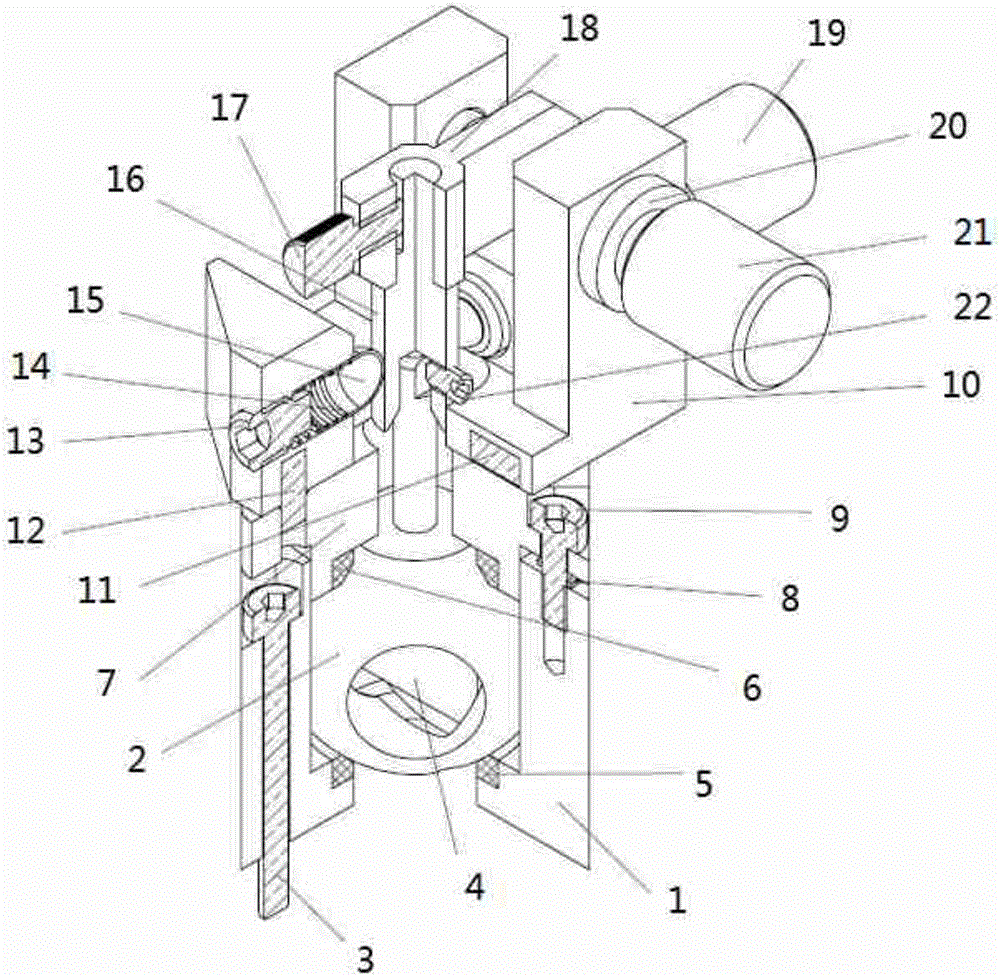

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

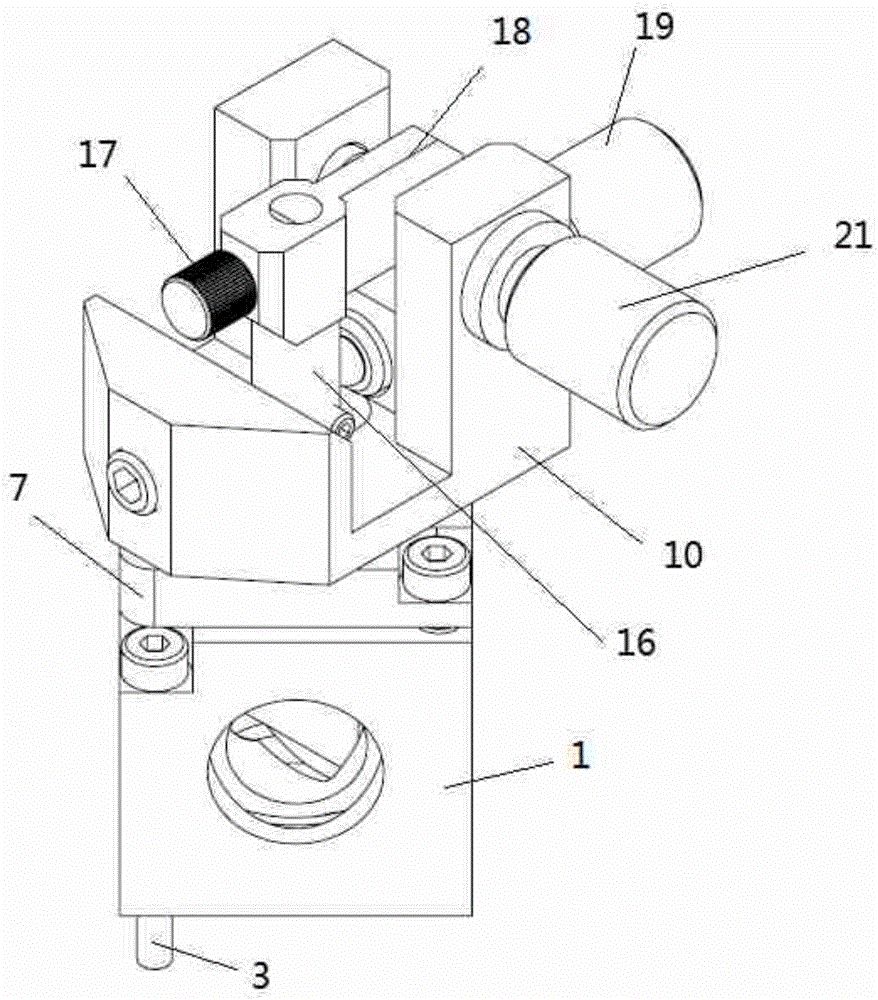

[0025] The present invention is a cage-type spherical split reflector universal adjustment structure, including a reflector fixing component and a universal adjustment component. For the adjustable reflector, the universal adjustment component is fixed on the reflector fixing component, and is used for adjusting the reflector. The adjustment component and the reflector fixing component are designed separately, and the adjustment component of the same adjustment structure can be shared, reducing unnecessary waste of resources.

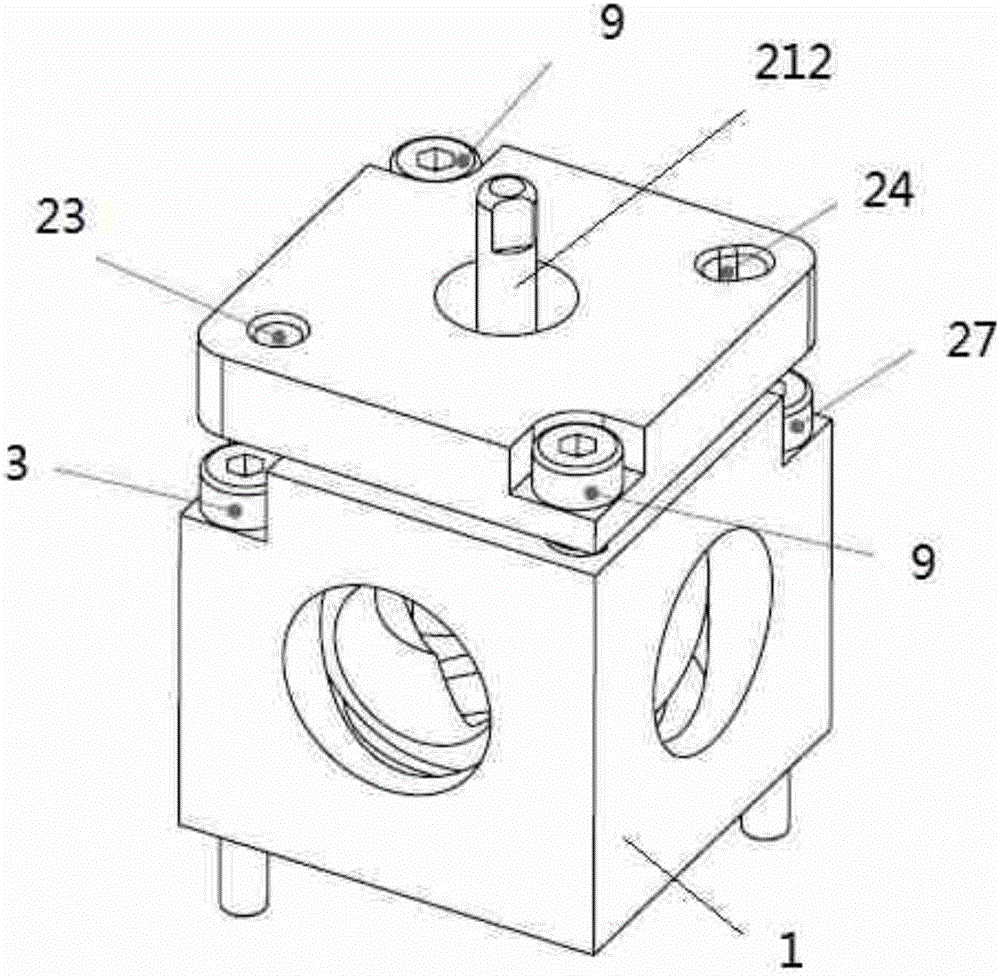

[0026] The mirror fixing assembly includes a cage frame 1 , a spherical frame 2 , a mirror 4 , and a cage frame cap 7 . The upper end of the cage frame 1 is open, the spherical frame 2 is arranged in the cage frame 1, the reflector 4 is bonded inside the spherical frame 2 and the center of the reflecting surface is at the spherical center of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap