Fuzz button inter-board electric connector

An electrical connector and wool button technology, applied in the field of electrical connectors between wool button boards, can solve the problems of increased gap between printed boards, difficult disassembly, inconvenient use, etc., and achieves zero insertion force, small size, contact Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

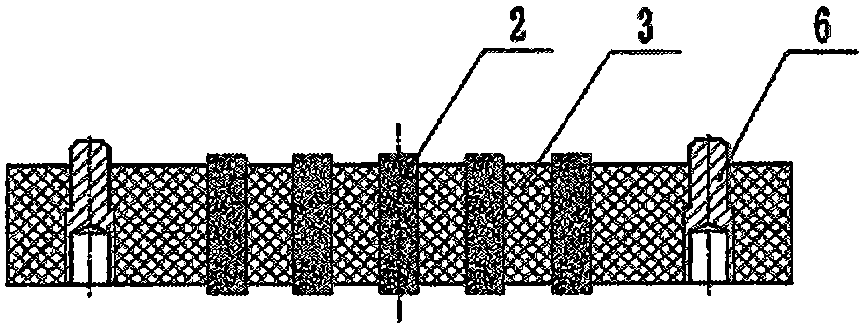

[0021] figure 1 It is a structural schematic diagram of an electrical connector between fur button boards. A group of messy wire pins 2 and accessories 6 are installed in the holes on the insulating mounting plate 3, and the two ends of the messy wire pins 2 are exposed on the insulating mounting plate 3. outside. The messy wire pin 2 is used as a contact piece, and the accessory 6 plays the role of guiding, locating and fixing the insulating mounting plate 3 .

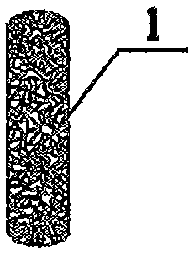

[0022] figure 2 is a schematic diagram of the structure of the random wire pin, and the random wire pin 2 is a cylindrical pin formed by randomly winding the metal wire 1 .

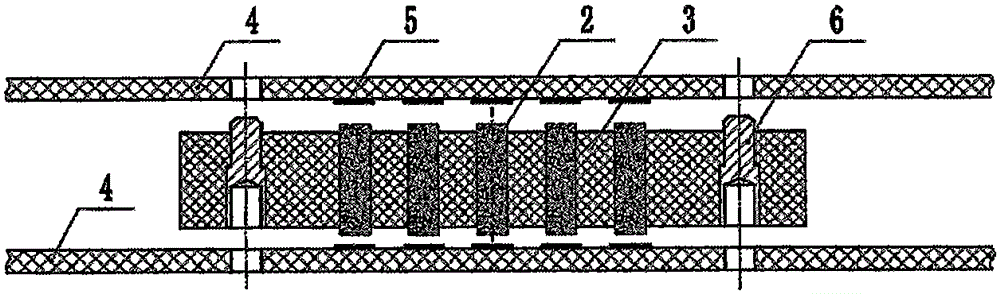

[0023] image 3 It is a schematic diagram before the vertical connection between the printed board and the printed board is realized by using the button-to-board electrical connector. Figure 4 It is a schematic diagram after the vertical connection between the printed board and the printed board is realized by using the button-to-board elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com