Graft copolymer, thermoplastic resin composition and molded article thereof

一种接枝共聚物、热塑性树脂的技术,应用在热塑性树脂组合物及其成型品领域,能够解决成型品表面外观恶化、润滑剂失去、润滑性降低等问题,达到流动性良好、耐冲击性优异、耐损伤性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

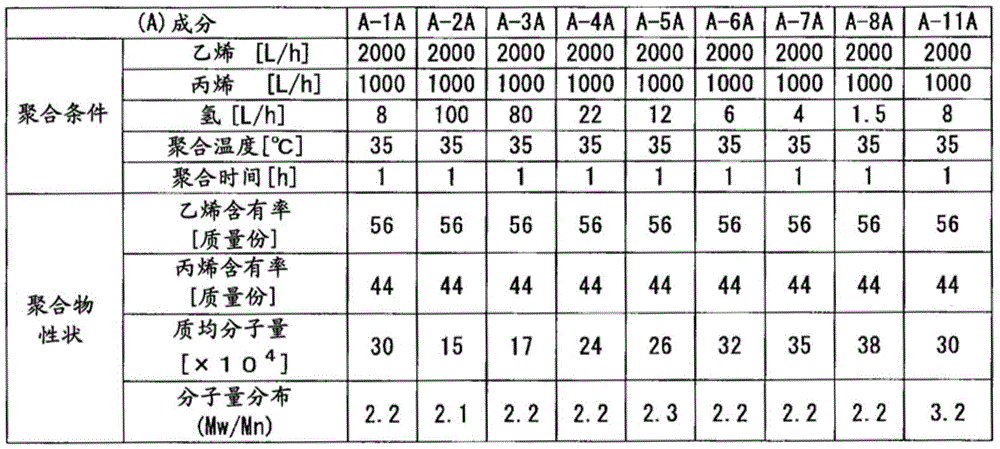

Embodiment 1A

[0750] "Example 1A"

[0751] Mix 28 parts of graft copolymer (D-1A), 72 parts of styrene-based copolymer (H-1A), and 0.5 parts of carbon black (manufactured by Mitsubishi Chemical Corporation, "#966"), and use A twin-screw extruder with a vacuum valve (manufactured by Ikegai Co., Ltd., "PCM30") was melt-kneaded at a cylinder temperature of 220° C. and a vacuum of 93.325 kPa to prepare a thermoplastic resin composition (1A). The results of measuring the MVR of the obtained thermoplastic resin composition (1A) are shown in Table 15A.

[0752] Separately, 28 parts of graft copolymer (D-1A), 72 parts of styrene-based copolymer (H-1A), and 0.8 parts of carbon black (manufactured by Mitsubishi Chemical Corporation, "#966") were mixed and used A twin-screw extruder with a vacuum valve (manufactured by Ikegai Co., Ltd., "PCM30") was melt-kneaded at a cylinder temperature of 220° C. and a vacuum of 93.325 kPa to prepare a thermoplastic resin composition (2A).

[0753] The obtained ...

Embodiment 1B

[0915] Mix 24 parts of graft copolymer (D-1B) and 76 parts of methacrylate resin (G-1B), use A twin-screw extruder with a vacuum valve (manufactured by Ikegai Co., Ltd., "PCM30") was melt-kneaded at 240° C. and 93.325 kPa in vacuum to prepare a thermoplastic resin composition. The MVR of the thermoplastic resin composition is shown in Table 22B.

[0916] The thermoplastic resin composition is granulated, various molded products are molded, the flexural modulus is measured, and the impact resistance, heat resistance, gloss, color development, scratch resistance, and scratch resistance are evaluated. The results are shown in Table 22B.

Embodiment 2B~33B

[0918] Except having changed the kind of graft copolymer (D) as shown in Table 22B - Table 27B, it carried out similarly to Example 1B, prepared the thermoplastic resin composition, and measured MVR.

[0919] The thermoplastic resin composition is granulated, various molded products are molded, the flexural modulus is measured, and the impact resistance, heat resistance, gloss, color development, scratch resistance, and scratch resistance are evaluated. The results are shown in Table 22B to Table 27B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com