A manganese-doped maghemite catalyst for thermocatalytic oxidation of formaldehyde and preparation method thereof

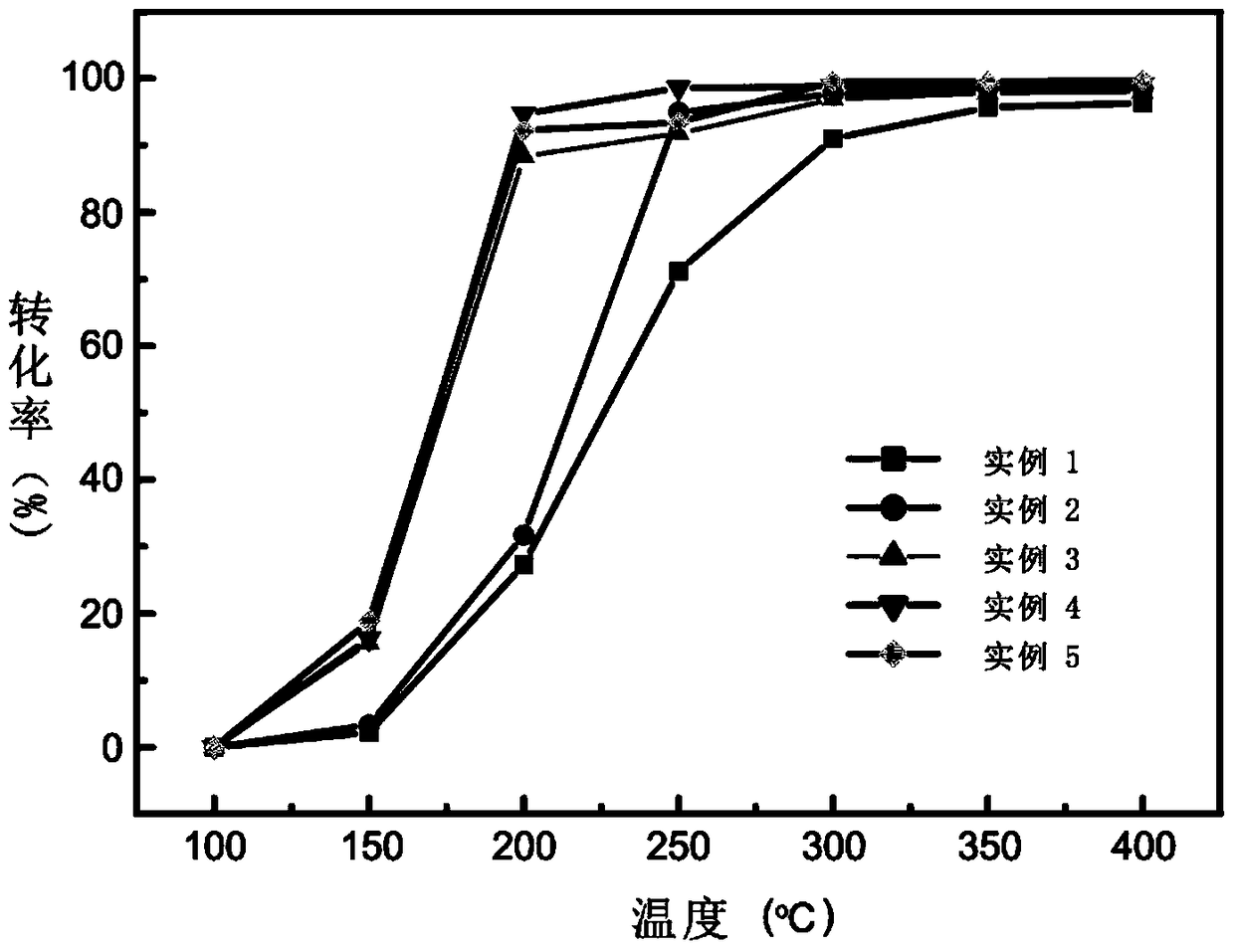

A technology of maghemite and manganese doping, which is applied in the field of manganese-doped maghemite catalyst and its preparation, can solve the problems of low catalytic activity, easy loss, high price, etc., and achieve high catalytic activity and light-off temperature Low, good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1. Weigh 27.8g FeSO 4 ·7H 2 O (0.1mol), 54.1g FeCl 3 ·6H 2 O (0.2mol) was added into 400mL ultrapure water (x=0), and under the protection of argon, it was completely dissolved to obtain 2+ , Fe 3+ solution of metal ions.

[0019] 2. Under the protection of argon, add the metal ion solution dropwise into 210mL of 4mol / L NaOH solution, and keep stirring the solution to form a black precipitate until the precipitation is complete; then crystallize the black precipitate at a constant temperature of 90°C for 24 hours .

[0020] 3. Centrifuge the black precipitate, collect the black precipitate, wash 3 times with ultrapure water, use a freeze dryer, freeze-dry in vacuum at a temperature of -40~-50°C for 24 hours, and obtain granular manganese-doped Magnetite precursor.

[0021] 4. Grading and screening Take the 35-60 mesh manganese-doped magnetite precursor, put it in a muffle furnace and roast it at 450° C. for 4 hours to obtain a composite sample 1 .

[0022] 5. Th...

Embodiment 2

[0024] 1. Weigh 22.2g FeSO 4 ·7H 2 O (0.08mol), 54.1g FeCl 3 ·6H 2 O (0.2mol), 3.4g MnSO 4 ·H 2 O (0.02mol) was added into 400mL ultrapure water (x=0.2), and under the protection of argon, it was completely dissolved to obtain 2+ , Fe 3 + , Mn 2+ solution of metal ions.

[0025] 2. Under the protection of argon, add the metal ion solution dropwise into 210mL of 4mol / L NaOH solution, and keep stirring the solution to form a black precipitate until the precipitation is complete; then crystallize the black precipitate at a constant temperature of 90°C for 24 hours .

[0026] 3. Centrifuge the black precipitate, collect the black precipitate, wash 3 times with ultrapure water, use a freeze dryer, and freeze-dry at a temperature of -40 to -50°C for 24 hours in a vacuum. After drying, granular manganese-doped magnetic Iron ore precursors.

[0027] 4. Grading and screening Take the 35-60 mesh manganese-doped magnetite precursor, put it in a muffle furnace and roast it at 4...

Embodiment 3

[0030] 1. Weigh 13.9g FeSO 4 ·7H 2 O (0.05mol), 54.1g FeCl 3 ·6H 2 O (0.2mol), 8.5g MnSO 4 ·H 2 O (0.05mol) was added into 400mL ultrapure water (x=0.5), and under the protection of argon, it was completely dissolved to obtain 2+ , Fe 3 + , Mn 2+ solution of metal ions.

[0031] 2. Under the protection of argon, add the metal ion solution dropwise into 210mL of 4mol / L NaOH solution, and keep stirring the solution to form a black precipitate until the precipitation is complete, and then crystallize the black precipitate at a constant temperature of 100°C for 24 hours .

[0032] 3. Centrifuge the black precipitate, collect the black precipitate, wash 3 times with ultrapure water, use a freeze dryer, and freeze-dry at a temperature of -40 to -50°C for 24 hours in a vacuum. After drying, granular manganese-doped magnetic Iron ore precursors.

[0033] 4. Grading and screening Take the 35-60 mesh manganese-doped magnetite precursor, put it in a muffle furnace and roast it a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com