Machining method for assisting line heating forming of ship hull plate by utilizing electromagnetic force

A technology for thermoforming and assisting the hull, applied in the field of hull hull plate forming and processing, can solve the problems of deterioration of steel plate material performance, low degree of automation, affecting forming efficiency, etc., and achieve the effect of promoting steel plate deformation, high versatility and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

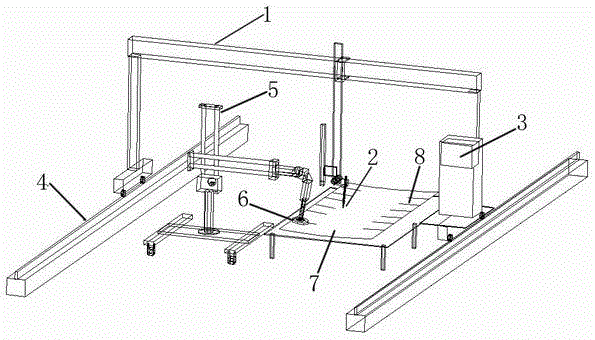

[0022] figure 1 A schematic diagram of the electromagnetic force assisted wire heating forming process device is shown. In the figure, during the online heating forming process, the electromagnetic force is used to assist the forming of the steel plate 7, and the electromagnetic coil 6 is placed above the steel plate 7, and its position can be adjusted. When the pulse current passes through the electromagnetic coil 6, the surrounding area of the electromagnetic coil 6 changes. Magnetic field, according to the law of electromagnetic induction, induced eddy currents will be generated in the steel plate 7 . Since the magnetic field generated by the electromagnetic coil 6 will act on the eddy current in the steel plate 7, the electromagnetic force that interacts between the electromagnetic coil 6 and the steel plate 7 is generated, which is divided into a radial electromagnetic force and an axial electromagnetic force. The radial electromagnetic force can be It has a radial ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com