Handheld electric grinder with shutdown braking device

A technology for stopping braking and grinding machines, which is applied in the directions of brake actuators, brake types, and axial brakes, which can solve problems such as reducing work efficiency, increasing work risk, and easily generating shaking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

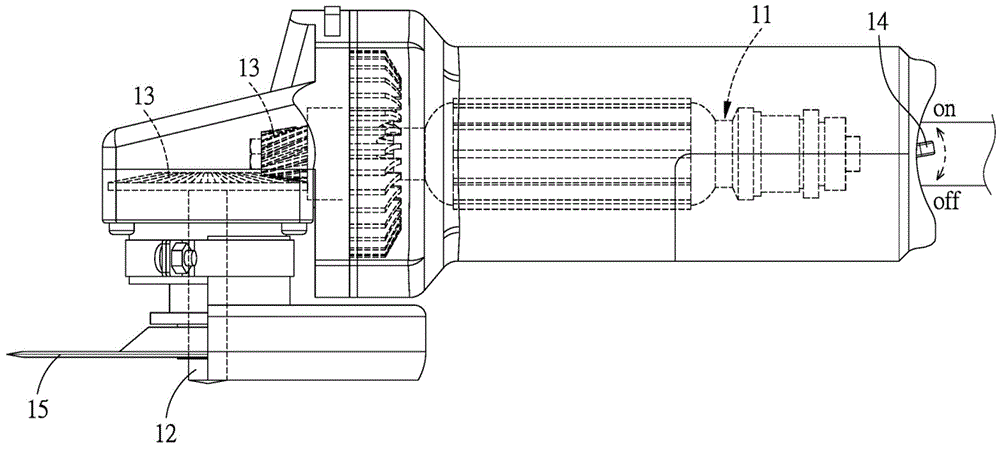

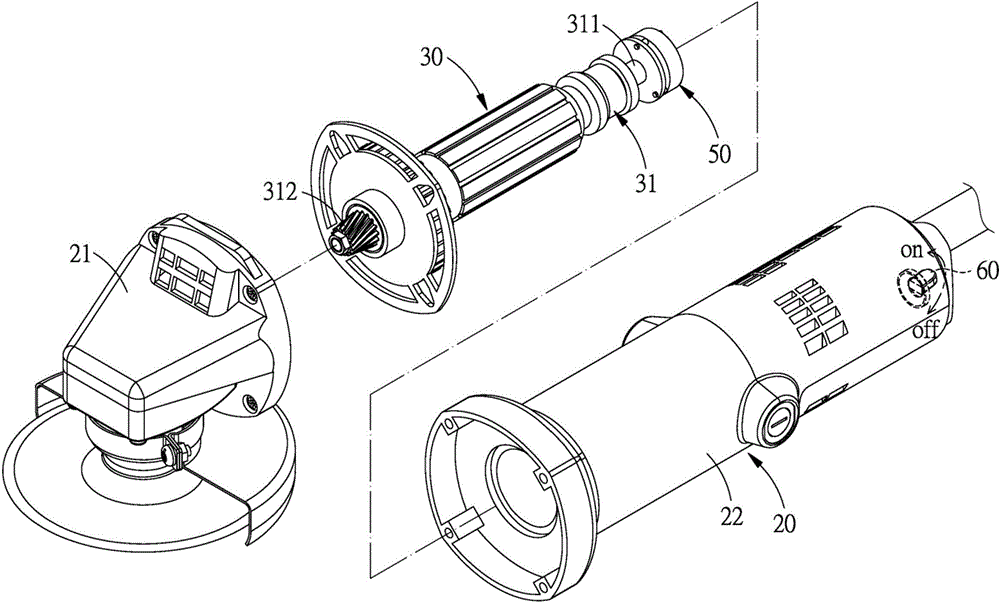

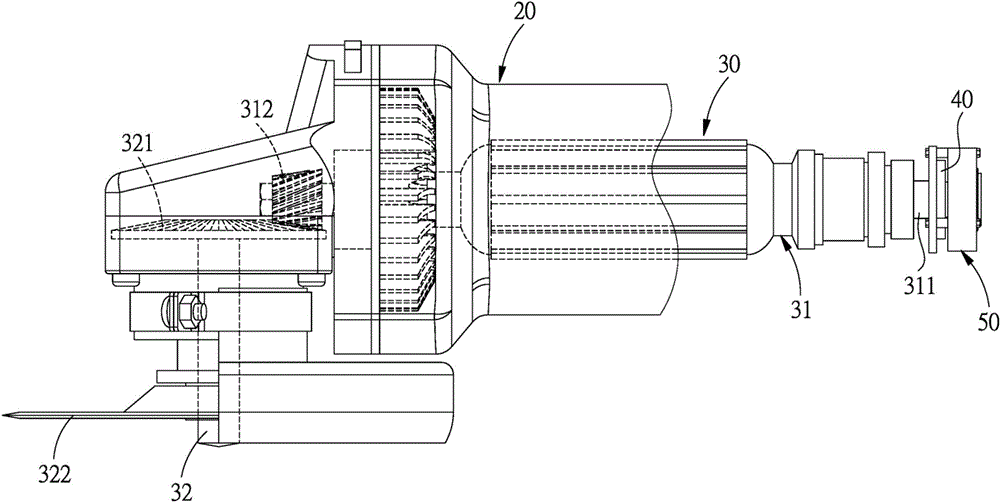

[0046] refer to Figure 2 to Figure 5 As shown, a hand-held electric grinder with a parking braking device provided by the first embodiment of the present invention mainly consists of a body 20, a rotating shaft unit 30, a brake disc 40, a braking device 50, and A power switch 60 is formed, wherein:

[0047] The body 20 is composed of a head 21 and a body 22 .

[0048] The shaft unit 30 is pivotally mounted on the body 20 and has a brake shaft portion 311; in this embodiment, the shaft unit 30 includes a motor shaft 31 and a grinding wheel shaft 32, one end of the motor shaft 31 is the Shaft 311, the other end of the motor 31 is fixed with a first bevel gear 312, one end of the grinding wheel shaft 32 is fixed with a second bevel gear 321 meshing with the first bevel gear 312, the other end of the grinding wheel shaft 32 A grinding wheel 322 is provided.

[0049] The brake disc 40 is fixed on the brake shaft portion 311 of the rotating shaft unit 30 and has a brake disc por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com