Motor train unit novel overall tea table installing structure

An installation structure and integrated technology, which is applied in the direction of railway car body parts, transportation and packaging, etc., can solve the problems of single function and poor space utilization, and achieve the effect of improving ride comfort, simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

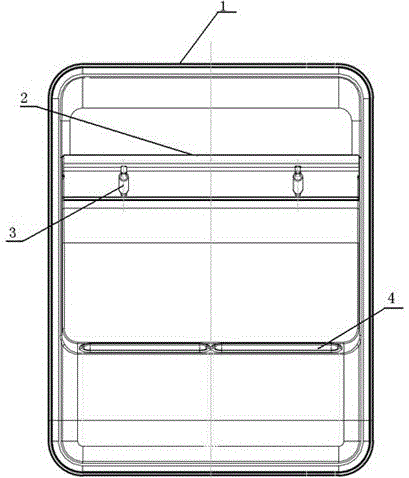

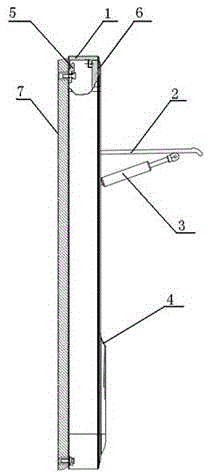

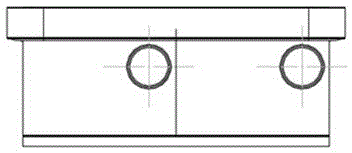

[0012] According to the interior seat arrangement of CRH5 vehicles is 3+2, so the overall tea table is divided into three-person overall tea table and two-person overall tea table.

[0013] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , the upper part of the glass fiber reinforced plastic overall cover plate 6 is processed with two or three grooves, the upper part of the groove is fixed and installed with the folding shaft through the folding shaft, and the other side of the folding tea table is connected through the gas spring 3, and the folding tea table After being put away, it is level with the overall cover plate 6 of FRP, and a through hole is provided on the bottom edge of the groove, and an open box body 4 is embedded in the through hole as a column for books and newspapers. The F-shaped outer frame 1 is connected around the overall cover plate of FRP, Hook 5 is installed on 7, and the F-shaped outer frame is articulated on the hook...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com