A high-speed aircraft functional partition combined wave-transmitting cover

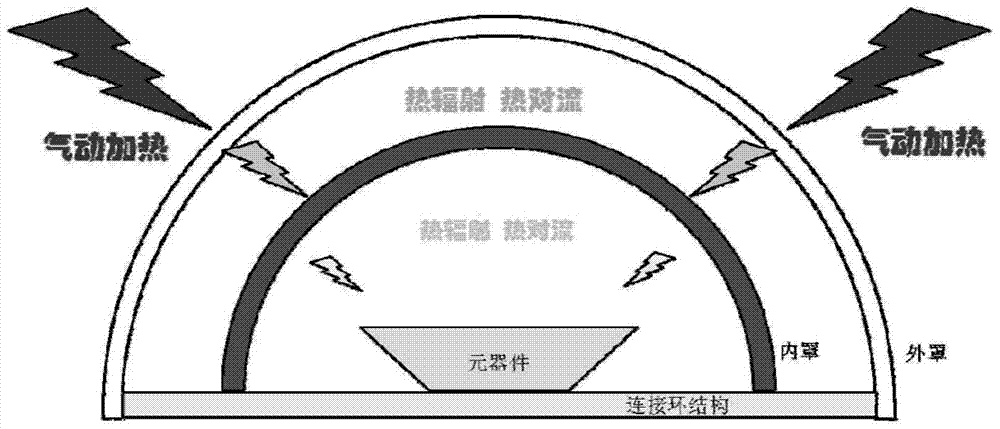

A high-speed aircraft and functional partitioning technology, applied in the field of wave-transmitting cover, can solve the problem of not being able to meet the requirements of the new high-speed aircraft's anti-heat insulation function, and achieve the effects of improving connection reliability, improving wave transmittance, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

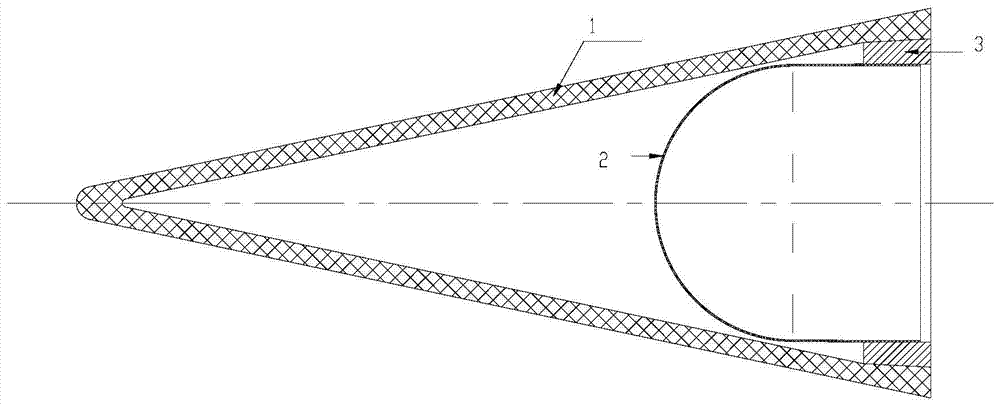

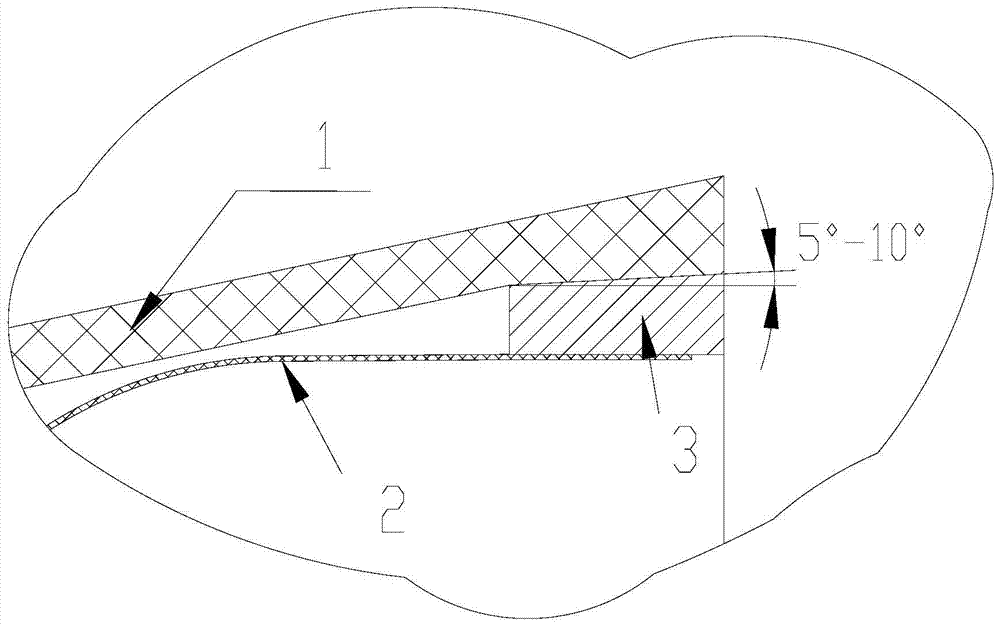

[0038] The outer cover 1 of the wave-transmitting cover is a cone, and the inner cover 2 is a combined structure of a hemisphere + a cylinder. The inner cover 2 is a structure of equal wall thickness, the wall thickness is 6mm, and the radius of the sphere and the cylinder is 170mm. The wall of the outer cover 1 The thickness varies between 15-20mm, the radius of the annular connecting ring 3 is 180-190mm, the position of the annular connecting ring 3 corresponds to the position of the cone on the inner surface of the outer cover 1, and the half-cone angle of the cone is 8°. The distance between the opening end surface of the outer cover 1 and the opening end surface of the inner cover 2 is 5 mm, and the opening end surface of the inner cover 2 is closer to the small end of the cover body.

[0039] The outer cover 1 is made of quartz fiber reinforced silica composite material, the inner cover 2 is made of polyimide composite material, and the connecting ring 3 is made of low expa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com